Industry information

Company News

- Unveiling the Charm and Applications of Punched Aluminum Veneers

- Ladies and gentlemen, today let's talk about the topic of customized aluminum veneer. You may feel like it's away from me

- Aluminum veneer customization, creating an artistic journey of personalized space

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics

- Punched aluminum veneer: a fashionable element in modern architecture

Industry dynamics

- Comparative analysis of aluminum veneer curtain wall prices

- The Fashion Beauty of Hyperbolic Aluminum Veneer: The New Trend of Aluminum Materials

- Aluminum veneer new trend: aesthetic revolution of modern architecture

- Construction process analysis of 3mm aluminum veneer in engineering

- Hyperbolic aluminum veneer: a fashionable choice for modern architecture

Frequently asked questions

- Is the production process of aluminum veneer environmentally friendly?

- What is the antioxidant performance of aluminum veneer?

- How does aluminum veneer provide the weather resistance required for modern buildings?

- What is the sound absorption effect of aluminum veneer?

- What is the seismic performance of aluminum veneer in building exterior design?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

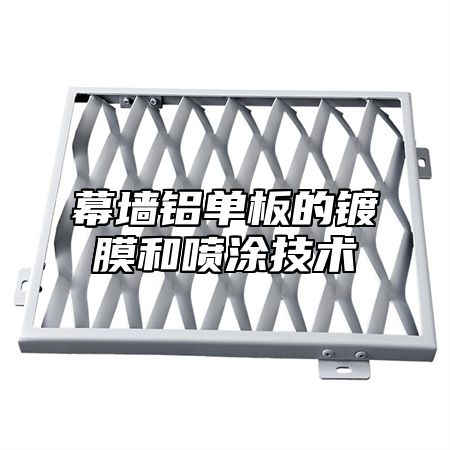

Coating and spraying technology for aluminum veneer of curtain wall

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-19 04:48:04

- Click:0

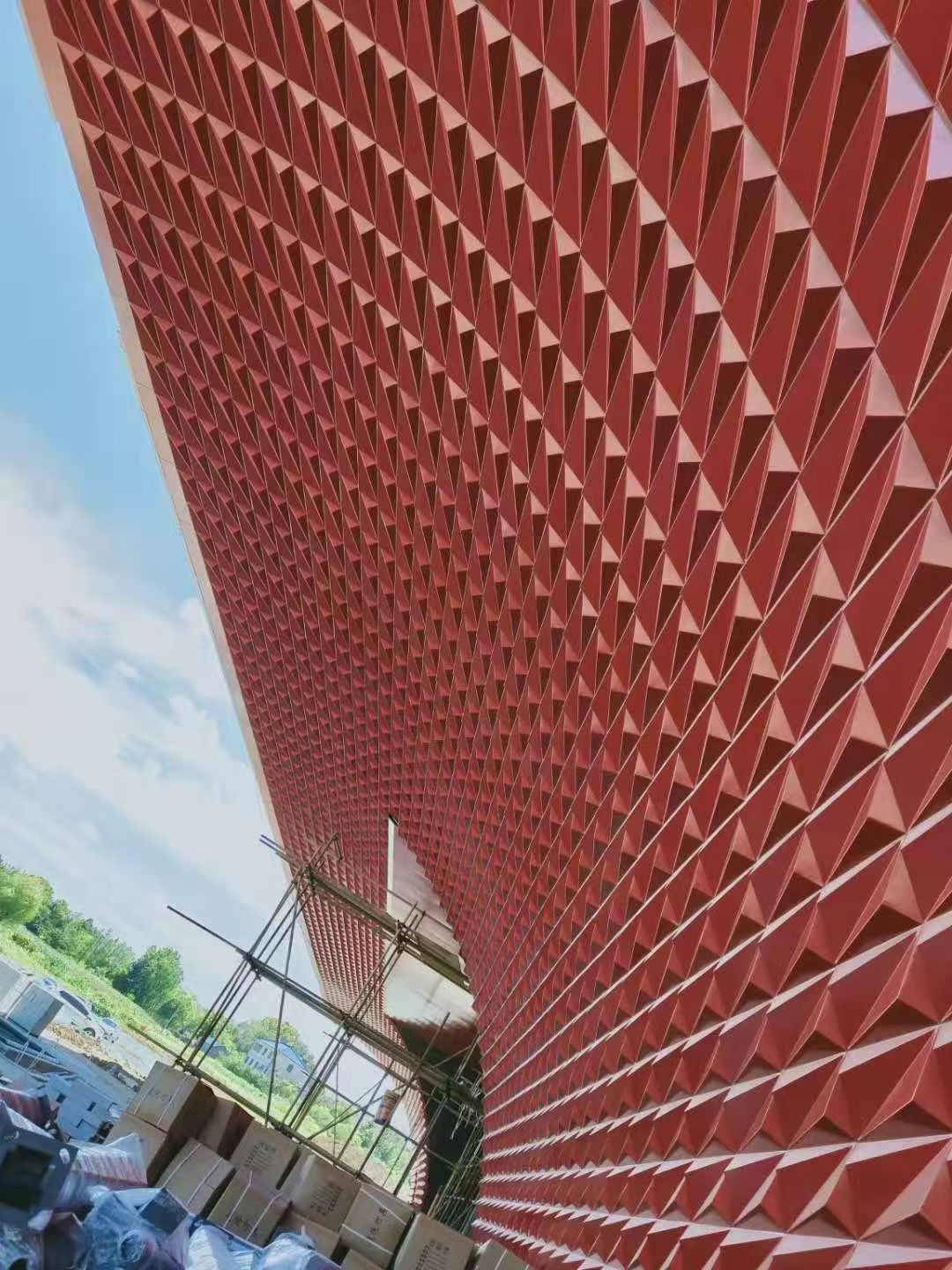

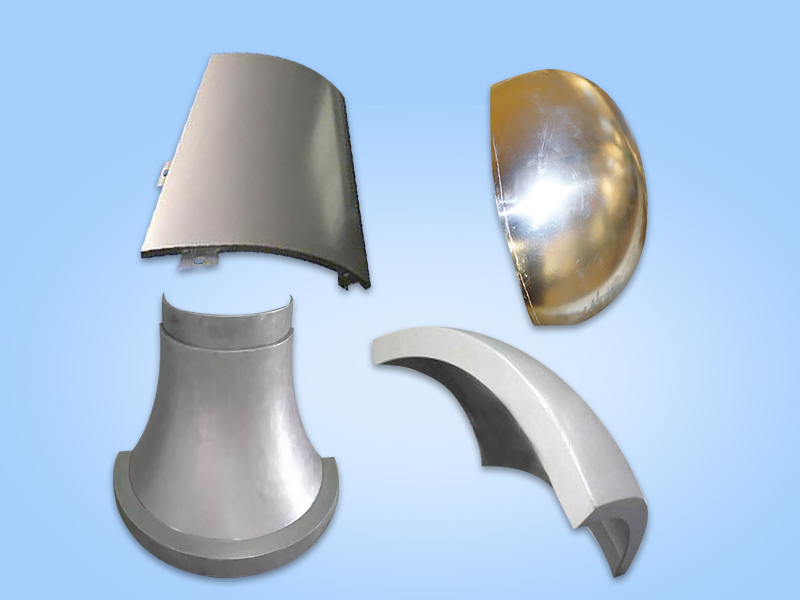

curtainAluminum veneerAs a common building decoration material, its coating and spraying technology has a significant impact on the appearance, durability, and corrosion resistance of the product. Below is a detailed introduction to the coating and spraying technology of curtain wall aluminum veneer.

1、 Coating technology

In terms of coating technology for curtain wall aluminum veneer, it mainly involves the following aspects:

1. Material selection: By selecting curtain wall aluminum veneer materials with good surface treatment properties, such as fluorocarbon coatings, the surface can be coated to enhance its corrosion resistance and aesthetics.

2. Process flow: Through specific process steps such as cleaning, primer, topcoat, etc., the coating is evenly applied to the surface of the curtain wall aluminum veneer to achieve the desired color and texture.

3. Quality control: Through strict quality control measures such as testing coating thickness, hardness, and other indicators, ensure that the surface treatment effect obtained meets the requirements.

2、 Spray coating technology

In terms of spraying technology for curtain wall aluminum veneer, it mainly involves the following aspects:

1. Material selection: By selecting curtain wall aluminum veneer materials with good surface treatment properties, such as fluorocarbon spraying, the surface can be sprayed to enhance its corrosion resistance and aesthetics.

2. Process flow: Through specific processes such as cleaning, primer, topcoat, etc., the coating is evenly sprayed onto the surface of the curtain wall aluminum veneer to achieve the desired color and texture.

3. Quality control: Through strict quality control measures such as testing coating thickness, hardness, and other indicators, ensure that the surface treatment effect obtained meets the requirements.

3、 Conclusion and Suggestions

When selecting and using curtain wall aluminum panels, attention should be paid to coating and spraying techniques to meet the overall aesthetic, practical, and anti-corrosion requirements of the building. It is also necessary to pay attention to the selection and control of material quality, process level, and other aspects to ensure the quality and effect of the curtain wall aluminum veneer. For suppliers, they can provide higher quality curtain wall aluminum veneer products and services by continuously optimizing product design, strengthening technological research and development, and meeting the needs of different customers. We also need to strengthen our awareness of environmental protection and responsibility, and actively promote the application and development of green environmental protection concepts in the curtain wall aluminum veneer industry.

Customer service QQ

Customer service QQ