Industry information

Company News

- Aluminum veneer customization, creating a new choice for personalized space!

- Hyperbolic aluminum veneer: the new darling of architectural aesthetics

- Punched aluminum veneer: Craftsmanship and innovative architectural style

- 2. "Exploring Hyperbolic Aluminum Veneer: An Architectural Miracle of Art and Technology Dancing Together!" 3 "...

- Punched aluminum veneer: infinite creativity, breathtaking beauty

Industry dynamics

- Hyperbolic aluminum veneer: the "Transformers" of the aluminum industry

- Hyperbolic aluminum veneer: the new darling of architectural aesthetics?

- What contribution does aluminum veneer make to energy conservation?

- Analysis of Production Cost and Market Price Investment Potential of Aluminum Veneer

- Aluminum veneer customization, creating a unique spatial aesthetic

Frequently asked questions

- What is the antioxidant performance of aluminum veneer?

- What impact does aluminum veneer have on the durability of buildings?

- Can aluminum veneer be used for building insulation design?

- Is there any restriction on the size customization of aluminum veneer?

- What are the advantages of aluminum veneer compared to other building materials in modern architecture?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Optimization and improvement of punching process for curtain wall aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-19 07:19:01

- Click:0

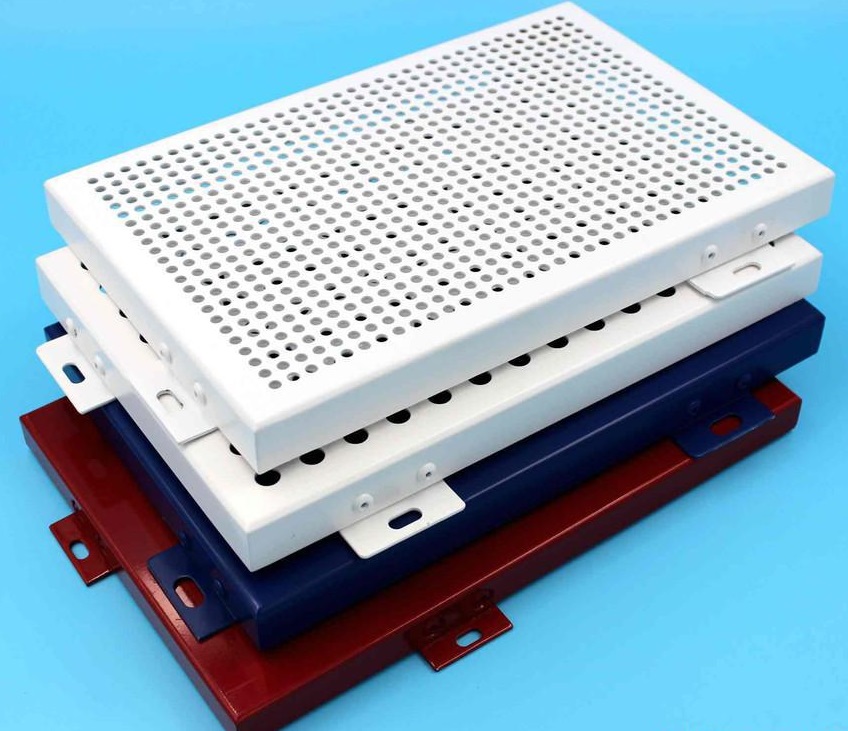

With the continuous development of the construction industry, curtain wallsAluminum veneerGradually becoming an important building material. Traditional aluminum veneer can no longer meet people's requirements for aesthetics and artistry. The application of punching technology for curtain wall aluminum veneer is also receiving increasing attention from people. Next, let's explore the optimization and improvement of punching process for curtain wall aluminum veneer.

1、 The necessity of optimizing and improving punching process

The traditional punching process for aluminum veneer in curtain walls has some problems, such as low punching accuracy, loud noise, and easy damage. These issues not only affect the aesthetics and practicality of buildings, but also waste human and material resources. It is necessary to optimize and improve the punching process of aluminum veneer for curtain walls.

2、 Methods for optimizing and improving punching processes

1. Optimize the performance of the punching machine

The performance of the punching machine directly affects the quality and efficiency of punching. Upgrading the hardware equipment or software system of the punching machine can improve its performance and achieve higher precision punching effects.

2. Optimize the material and shape of punching tools

The material and shape of punching tools are also important factors affecting punching quality. By selecting higher quality materials and designing more reasonable tool shapes, the accuracy and efficiency of punching can be improved.

3. Optimize the punching process flow

By adjusting the punching process flow, the noise and vibration generated during the punching process can be reduced, the equipment damage rate can be lowered, and production efficiency and product quality can be improved.

4. Introduce an automated control system

The introduction of an automated control system can achieve automated control of the punching process, thereby improving production efficiency and product quality. It can also reduce errors and losses in manual operations, improve production efficiency and economic benefits.

3、 Case sharing

Let's take a look at an optimization and improvement case of punching process for curtain wall aluminum veneer: a company designed a high-rise building in a commercial center of a city, and the exterior wall of the building used multiple punched curtain wall aluminum veneer panels of different colors and shapes for combination and assembly. During the construction process, due to some problems with traditional punching techniques, some aluminum veneer punching was incomplete or deviated. To address these issues, the company has introduced advanced automation control systems and new punching tools, and optimized and improved the punching process flow. Ultimately, high-precision and high-quality punching effects were achieved, improving the overall aesthetics and practicality of the building.

4、 Summary

The optimization and improvement of punching process for curtain wall aluminum veneer is necessary. By upgrading punching machines, optimizing punching tools, adjusting punching process flow, and introducing automation control systems, the accuracy and efficiency of punching can be improved, the damage rate of equipment can be reduced, and production efficiency and product quality can be improved. In the future, with the continuous progress and innovation of technology, it is believed that the punching process of curtain wall aluminum veneer will be more widely applied and developed. It also requires practitioners in the construction and decoration industry to constantly learn and explore in order to adapt to market demands and changes.

Customer service QQ

Customer service QQ