Industry information

Company News

- Aluminum veneer: the 'hidden hero' of modern architecture

- Lightweight Wings: Unveiling the Aesthetic Charm of Hyperbolic Aluminum Veneers

- Hyperbolic aluminum veneer: the aesthetic new favorite of modern architecture

- Hyperbolic aluminum veneer: the new darling of architectural art

- Hyperbolic aluminum veneer leads the new trend of architectural aesthetics!

Industry dynamics

- Hyperbolic aluminum veneer, the fashionable new favorite of modern architecture

- Hyperbolic aluminum veneer, the new darling of art in the aluminum industry!

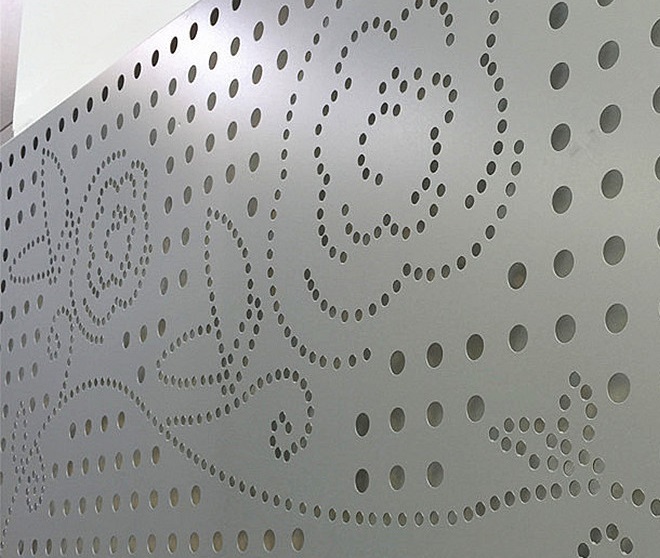

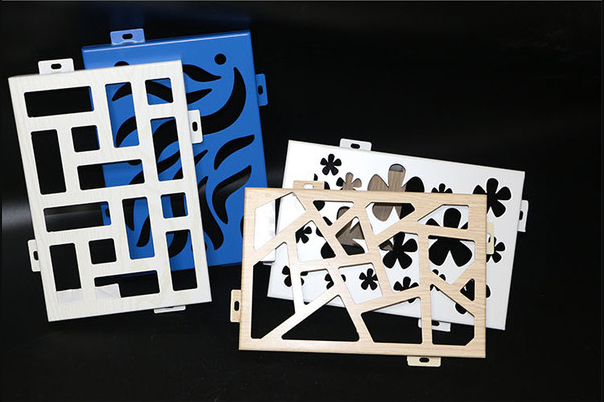

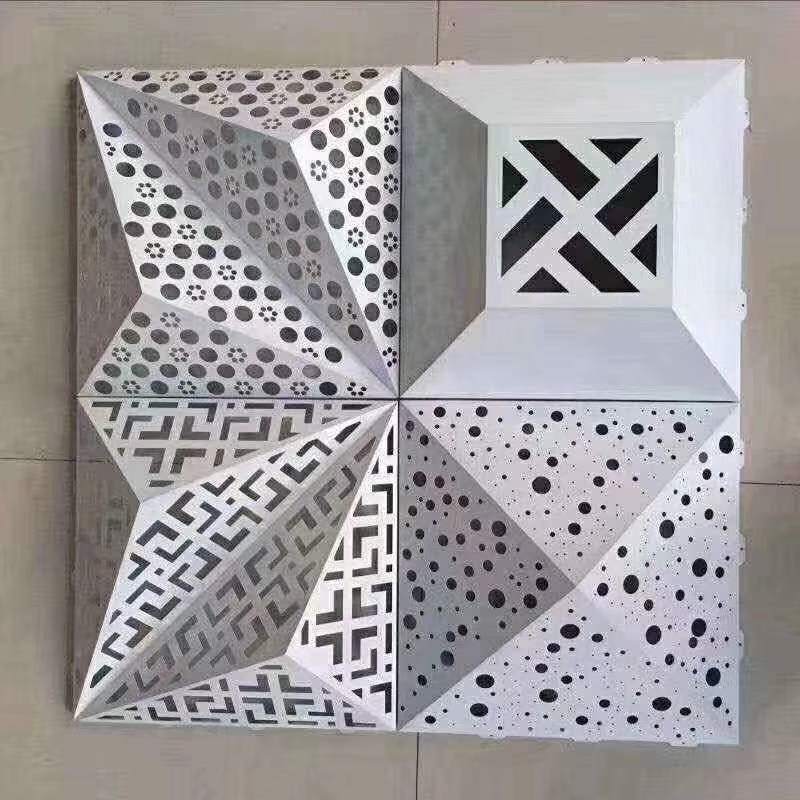

- Punched aluminum veneer: a fashionable choice in modern architecture

- Can aluminum veneer be used for building canopy design?

- Punched aluminum veneer: the fashionable choice for modern architecture?

Frequently asked questions

- Can aluminum veneer be used for building insulation design?

- Is the production process of aluminum veneer environmentally friendly?

- What is the seismic performance of aluminum veneer in building exterior design?

- What is the antioxidant performance of aluminum veneer?

- Is there any restriction on the size customization of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Aluminum veneer installation technology and process

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 21, 2025 09:08:01

- Click:0

Aluminum veneerAs a lightweight and high-strength building material, it has been widely used in modern architecture. The installation process requires certain technology and craftsmanship to ensure its quality and aesthetics. This article will provide a detailed introduction to the installation technology and process of aluminum veneer.

1. Preparation work

Before installing aluminum veneer, the following preparations need to be made:

(1) Determine the installation position and angle, and measure and mark according to the design requirements.

(2) Check whether the quality and quantity of aluminum veneer meet the requirements, and replace or repair any non-conforming materials.

(3) Prepare the necessary tools and equipment, such as electric drills, cutting machines, corner codes, etc.

(4) Clean the installation site to ensure a smooth, dry, and dust-free surface.

1. Installation steps

The installation steps for aluminum veneer are as follows:

(1) Lay a foundation in the installation position and use a spirit level to check if it is level.

(2) Use an electric drill and corner code to fix the aluminum veneer on the foundation, paying attention to maintaining the horizontal and vertical alignment of the aluminum veneer.

(3) For longer aluminum veneers, splicing can be used for installation, but attention should be paid to the sealing treatment at the interface to prevent rainwater from seeping in.

(4) For areas that require drilling, electric saws or cutting machines can be used for cutting, and corner codes can be used for fixation.

(5) After installation, the aluminum veneer should be inspected and adjusted to ensure its flatness and verticality meet the requirements.

1. Precautions

During the installation process of aluminum veneer, the following precautions should be taken:

(1) Before installation, carefully read the design drawings and technical requirements, and make adjustments and modifications according to the actual situation.

(2) During the installation process, attention should be paid to maintaining the level and verticality of the aluminum veneer to avoid affecting its appearance and service life.

(3) For areas that require drilling, care should be taken to avoid damaging the structure and surface of the aluminum veneer.

(4) After installation, timely cleaning and protective treatment should be carried out to extend the service life of aluminum veneer.

The installation technology and process of aluminum veneer are very important to ensure its quality and aesthetics. During the installation process, attention should be paid to selecting appropriate tools and equipment, and operating according to the design requirements. Attention should also be paid to safety and environmental issues to avoid pollution and damage to the environment.

Customer service QQ

Customer service QQ