Industry information

Company News

- Aluminum veneer customization, creating a new proposition for personalized space!

- Fluorocarbon aluminum veneer: the new luxury of aluminum materials, the beauty of architecture

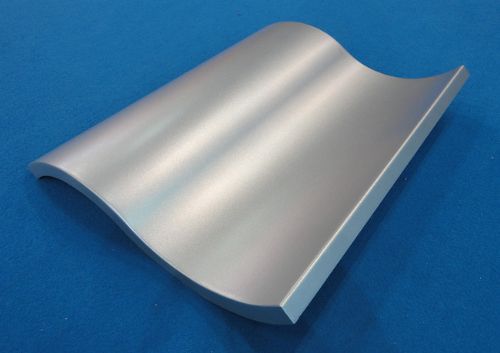

- Hyperbolic aluminum veneer: a unique choice for future architectural art?

- Aluminum veneer customization, creating personalized space art

- Unveiling the magical charm of fluorocarbon aluminum veneer

Industry dynamics

- Seismic performance testing of imitation wood grain aluminum veneer

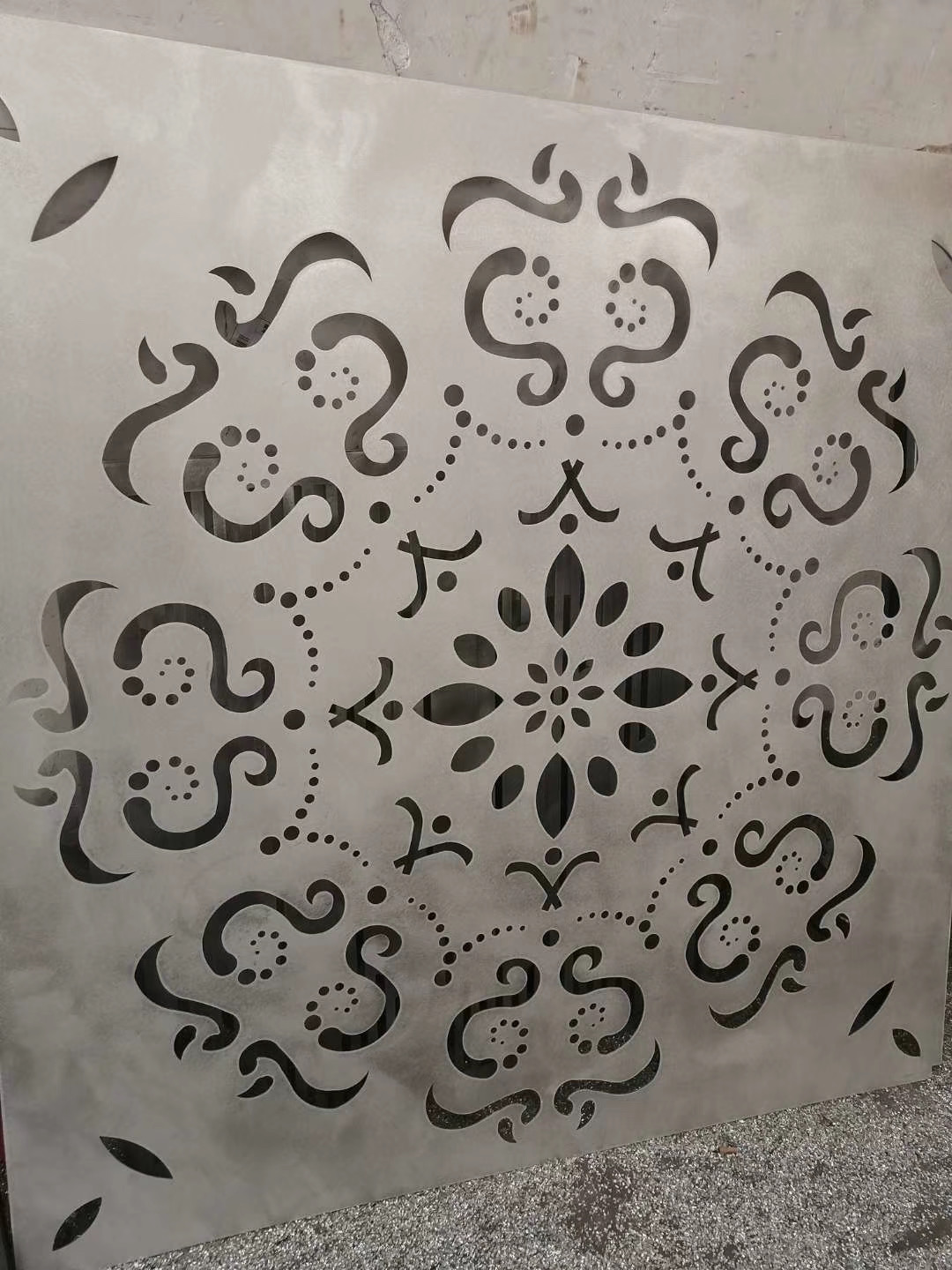

- The artistic charm of carved aluminum veneer at the entrance of classical aesthetics

- Customize aluminum veneer to create personalized spatial aesthetics

- 2. "Aluminum veneer deformation record: The beauty of hyperbolic curves lies in the details!" 3 Exploring Hyperbolic

- What climatic conditions is fluorocarbon aluminum veneer suitable for?

Frequently asked questions

- Can the insulation function of aluminum veneer reduce the energy consumption of buildings?

- Is the production process of aluminum veneer environmentally friendly?

- What is the antioxidant performance of aluminum veneer?

- How does aluminum veneer provide the weather resistance required for modern buildings?

- Is there any restriction on the size customization of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Precautions for installation of 2.5mm ceiling aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 2, 2025 15:04:18

- Click:0

2.5mm ceilingAluminum veneerThe installation is an important part of ensuring its aesthetics and service life. Below, we will provide a detailed introduction to the installation precautions for 2.5mm ceiling aluminum veneer.

1、 Preparation work

1. Determine the installation location

Before installing the 2.5mm ceiling aluminum veneer, it is necessary to first determine its installation position. Generally speaking, aluminum veneers should be installed at the top or middle of buildings for decorative and shading purposes.

2. Check the keel and suspension rod

Before installation, it is necessary to inspect the keel and suspension rod to ensure their quality and stability. If any damage or deformation is found, it needs to be replaced or repaired in a timely manner.

3. Prepare tools and materials

Before installation, it is necessary to prepare necessary tools and materials such as drills, screwdrivers, level gauges, etc. At the same time, sufficient aluminum veneer and other accessories need to be prepared to ensure the smooth progress of installation work.

2、 Installation steps

1. Install the suspension rod

Firstly, it is necessary to fix the suspension rod on the keel according to the design requirements and adjust it using a level to ensure the levelness and verticality of the suspension rod. Then connect the suspension rod to the aluminum veneer and fix it on the suspension rod with screws.

2. Install aluminum veneer

After connecting the suspension rod to the aluminum veneer, the installation of the aluminum veneer can begin. Firstly, the aluminum veneer needs to be placed on the suspension rod and adjusted using a level to ensure its flatness and levelness. Then use screws to secure it to the suspension rod.

3. Install the border strip

After installing the aluminum veneer, it is necessary to install edge strips to ensure that the edges of the aluminum veneer are neat and beautiful. Firstly, it is necessary to measure the size of the edge of the aluminum veneer and select the appropriate edge strip for installation based on the measurement results. Then use screws to fix it on the edge of the aluminum veneer.

3、 Precautions

1. Temperature control

During the installation process of 2.5mm suspended aluminum panels, attention should be paid to the temperature of the environment to avoid deformation or cracking of the aluminum panels due to temperature changes. Especially during winter construction, measures need to be taken to maintain stable indoor temperature to avoid affecting the quality of aluminum veneer.

2. Moisture proof treatment

Due to the water absorption of 2.5mm ceiling aluminum veneer, it is necessary to perform moisture-proof treatment before installation. Waterproof coating or coating with a protective film can be used for treatment to prevent the aluminum veneer from being affected by moisture and affecting its service life.

3. Safety protection

During the construction process, it is necessary to pay attention to safety protection measures to avoid accidents. Especially when using welding machines and other equipment, it is necessary to strictly follow the relevant safety operating procedures to ensure the safety and reliability of the construction process.

4. Quality inspection

After installation, it is necessary to conduct quality inspection on the aluminum veneer to ensure that it meets the design requirements and national standards. Especially, attention should be paid to checking the flatness, verticality, and levelness of the aluminum veneer to ensure its aesthetics and service life.

The installation of 2.5mm suspended aluminum veneer requires attention to preparation work, installation steps, and precautions. In future architectural design, with the increasing demand for building materials, 2.5mm ceiling aluminum veneer will be more widely used.

Customer service QQ

Customer service QQ