Industry information

Company News

- Aluminum veneer customization, creating an artistic journey of personalized space

- Punched aluminum veneer: the "fashionable skin" of modern architecture

- Hyperbolic aluminum veneer, creating a new trend in modern architecture!

- Hyperbolic aluminum veneer: the aesthetic new favorite of modern architecture

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

Industry dynamics

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer, creating the beauty of modern architecture

- Aluminum veneer customization, creating a unique spatial aesthetic

- Exploration of Carving Techniques: The Artistic Beauty of Carving Aluminum Veneers with Pillars

- Analysis of Quality Assurance and Technical Advantages of Wave 1.5mm Aluminum Veneer

Frequently asked questions

- Is there any restriction on the size customization of aluminum veneer?

- What are the advantages of aluminum veneer compared to other building materials in modern architecture?

- How does aluminum veneer provide the weather resistance required for modern buildings?

- What is the antioxidant performance of aluminum veneer?

- What is the seismic performance of aluminum veneer in building exterior design?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

2.0mm aluminum veneer baking paint process and characteristics

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 26, 2025 23:58:11

- Click:0

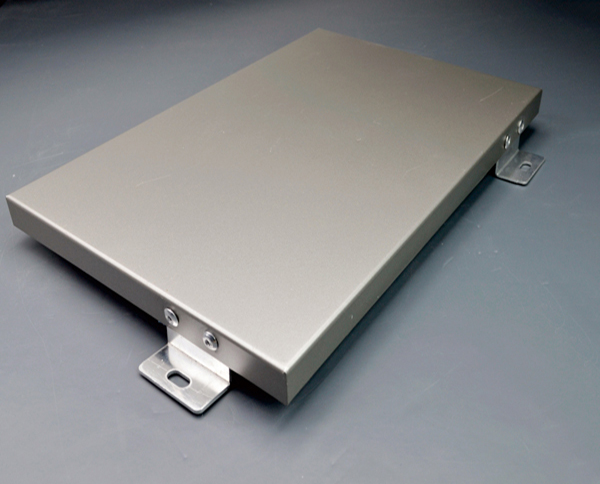

2.0mmAluminum veneerThe baking paint process is a common building decoration material, characterized by a smooth surface, rich colors, and strong corrosion resistance. This article will provide a detailed introduction to the characteristics and application scope of the 2.0mm aluminum veneer baking paint process.

1、 Characteristics

1. Smooth surface: The 2.0mm aluminum veneer baking paint process can make the surface of the aluminum veneer as smooth as a mirror, with good reflection effect, which can effectively enhance the visual effect of the building.

2. Rich colors: The 2.0mm aluminum veneer baking paint process can be sprayed in multiple colors according to needs, which can meet the needs of different architectural styles and also increase the aesthetics of buildings.

3. Strong corrosion resistance: The 2.0mm aluminum veneer baking paint process can form a dense oxide film on the surface of the aluminum veneer, which can effectively prevent oxidation and corrosion of the aluminum veneer and extend its service life.

2、 Application scope

1. Interior decoration: The 2.0mm aluminum veneer baking paint process can be used in the field of interior decoration, such as ceilings, partitions, doors, etc. Its smooth surface and rich colors can add beauty to indoor spaces.

2. Outdoor curtain wall: The 2.0mm aluminum veneer baking paint process can be used in the field of outdoor curtain walls, such as commercial buildings, residential buildings, etc. Its smooth surface and rich colors can add a sense of luxury and modernity to buildings.

3. Transportation field: The 2.0mm aluminum veneer baking paint process can be used in the transportation field, such as subway stations, airports, etc. Its smooth surface and strong corrosion resistance can ensure the safety and stability of buildings.

3、 2.0mm aluminum veneer baking paint process flow

The 2.0mm aluminum veneer baking paint process mainly consists of the following steps:

1. Cleaning: Firstly, the aluminum veneer needs to be cleaned to remove surface dirt and grease.

2. Polishing: After cleaning, the aluminum veneer needs to be polished to make its surface smoother.

3. Spray primer: After polishing, a layer of primer needs to be sprayed to enhance the adhesion and durability of the aluminum veneer surface.

4. Spray topcoat: After the primer dries, a layer of topcoat needs to be sprayed to enhance the color and glossiness of the aluminum veneer surface.

5. Baking: Finally, the sprayed aluminum veneer needs to be baked to make its surface smoother and more firm.

Customer service QQ

Customer service QQ