Industry information

Company News

- Unveiling the Charm and Wide Application of Fluorocarbon Aluminum Veneer

- The secret of aluminum veneer: the perfect fusion of lightness and durability

- Fluorocarbon aluminum veneer: the new darling of modern architecture

- Fluorocarbon aluminum veneer, the "green new clothes" of modern architecture

- Aluminum veneer customization, creating personalized space art

Industry dynamics

- Aluminum veneer door head manufacturer direct sales 1.5mm aluminum veneer customization

- Punched aluminum veneer: a fashionable choice in modern architecture

- Aluminum veneer customization, creating a new proposition for personalized space!

- Hyperbolic aluminum veneer, the new favorite of modern architecture?

- Unveiling Fluorocarbon Aluminum Veneer: The Secret Weapon of Architectural Aesthetics!

Frequently asked questions

- What is the sound absorption effect of aluminum veneer?

- How does aluminum veneer provide the weather resistance required for modern buildings?

- What impact does aluminum veneer have on the durability of buildings?

- Is the production process of aluminum veneer environmentally friendly?

- Can aluminum veneer be used for building insulation design?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Construction process analysis of 3mm aluminum veneer in engineering

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-18 08:12:53

- Click:0

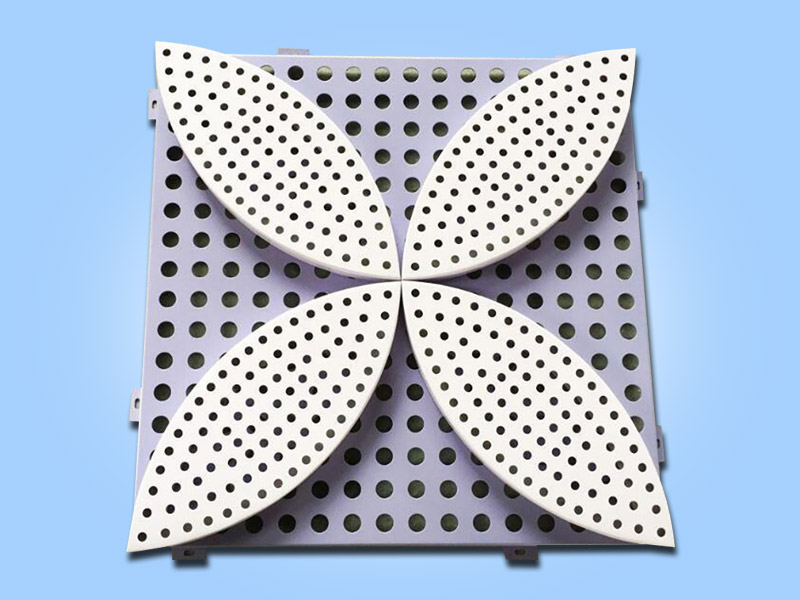

Aluminum veneerIt is a common building material that has been widely used in modern architecture. In the construction process of aluminum veneer, certain procedures and specifications need to be followed to ensure its quality and stability. This article will provide a detailed introduction to the construction process of 3mm thick aluminum veneer from the following aspects.

1、 Preparation work

1. Material preparation: Before construction, it is necessary to inspect and prepare the required aluminum veneer, keel, accessories, etc. If aluminum veneers require anodizing treatment, corresponding treatment equipment and chemicals should be prepared in advance.

2. On site layout: At the construction site, detailed planning and layout of the position, size, installation method, etc. of the aluminum veneer are required. We also need to consider the safety of construction personnel and the hygiene of the construction environment.

2、 Install the keel

1. Keel making: Before installing the keel, it is necessary to make the corresponding keel first. The production of dragon bones should comply with relevant specifications and standards, such as using high-strength steel or aluminum alloy materials, and undergoing anti-corrosion treatment.

2. Keel installation: When installing the keel, it is necessary to measure and mark according to the design requirements, and then install it according to the predetermined position and angle. During the installation process, attention should be paid to the flatness and verticality of the keel to ensure the installation quality of the aluminum veneer.

3、 Install aluminum veneer

1. Aluminum veneer positioning: Before installing the aluminum veneer, its position needs to be accurately positioned and marked. For large buildings, tools such as laser rangefinders can be used for measurement and positioning; For small buildings, simple tools such as a level can be used for measurement.

2. Aluminum veneer fixing: When installing the aluminum veneer, it is necessary to use screws or other fixing parts to fix it on the keel. During the fixing process, it is necessary to pay attention to whether the direction and position of the aluminum veneer are correct to ensure its aesthetics and stability.

4、 Closing work

1. Cleaning work: After the construction is completed, the site needs to be cleaned and organized. Such as removing dust and dirt from the surface of aluminum veneer, as well as dismantling temporary scaffolding.

2. Acceptance work: After the construction is completed, the entire project needs to be accepted. The acceptance content includes the quality, stability, safety, and other aspects of aluminum veneer to ensure that the entire project complies with relevant specifications and standards.

5、 Summary

The construction process of 3mm thick aluminum veneer includes preparation work, installation of keel, installation of aluminum veneer, and finishing work. Only by strictly following relevant specifications and standards can the quality and stability of aluminum veneer be guaranteed, while also achieving good decorative effects. In the actual construction process, attention should be paid to details and safety issues, and operations should be strictly carried out in accordance with relevant specifications to ensure the safety and stability of the entire project.

Customer service QQ

Customer service QQ