Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer, the fashion "new favorite" in the construction industry

- Explore the unique charm of hyperbolic aluminum veneer

- Hyperbolic aluminum veneer: innovative materials, new trends in future construction!

- The Charm of Aluminum Veneer: The Perfect Fusion of Lightweight and Texture

Industry dynamics

- Hyperbolic aluminum veneer, a masterpiece of art in the aluminum industry!

- Installation method of 2.5mm aluminum veneer

- How does the plasticity of aluminum veneer affect the architectural form?

- Punched aluminum veneer: unlimited creativity and wide application!

- Exploring the Charm and Secrets of Hyperbolic Aluminum Veneer

Frequently asked questions

- Is the production process of aluminum veneer environmentally friendly?

- How does aluminum veneer provide the weather resistance required for modern buildings?

- What is the seismic performance of aluminum veneer in building exterior design?

- What is the sound absorption effect of aluminum veneer?

- Can aluminum veneer be used for building insulation design?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Manufacturing method and process flow of perforated roller coated aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-09 22:43:16

- Click:0

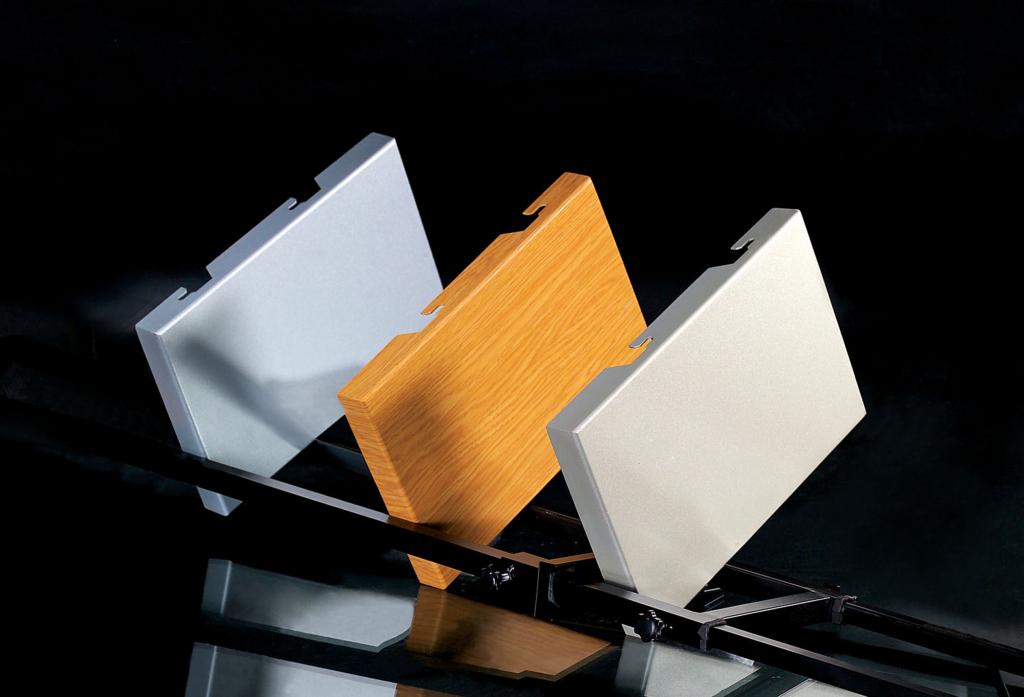

Perforated roller coatingAluminum veneerIt is a new type of building material, and its production method and process have a crucial impact on its application effect. The following will provide a detailed introduction to the production method and process flow of perforated roller coated aluminum veneer from multiple perspectives.

1、 Raw material preparation

Select high-quality aluminum alloy sheets as raw materials and perform surface treatment to ensure surface smoothness and flatness. It is also necessary to prepare relevant coatings and auxiliary materials, such as curing agents, diluents, pigments, etc.

2、 Kaiping Processing

Process the aluminum alloy sheet according to the design requirements to form the required size and shape. This step is a crucial one that requires ensuring machining accuracy and quality to ensure the smooth progress of subsequent processes.

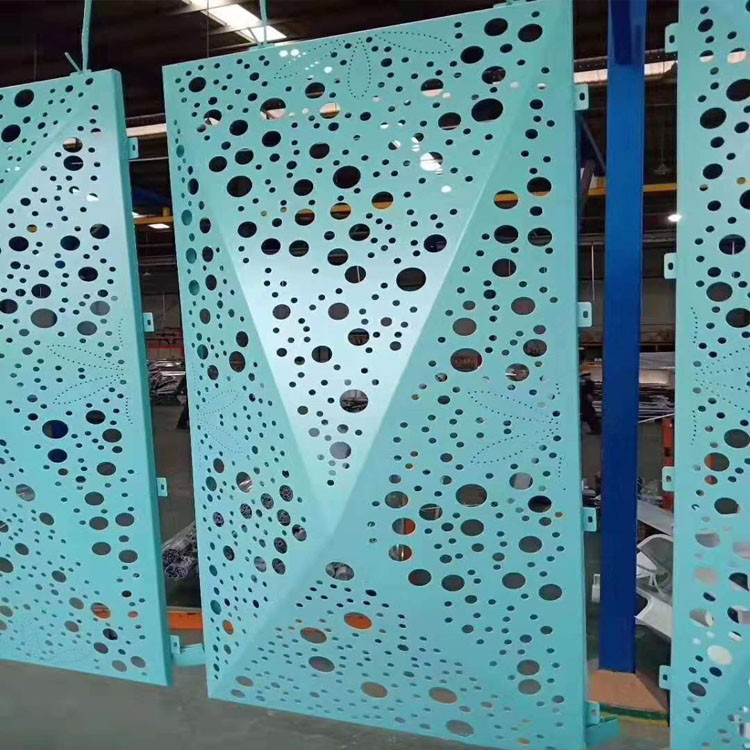

3、 Perforation processing

Perforation processing is performed on aluminum alloy sheets to form the desired perforation structure. This step requires the use of professional perforation equipment and technology to ensure the accuracy and quantity of perforation structures.

4、 Spray treatment

Spray the perforated aluminum alloy sheet to increase its corrosion resistance and decorative value. This step requires the use of professional spraying equipment and techniques to ensure the quality and uniformity of the coating.

5、 Quality inspection packaging

Inspect the perforated roller coated aluminum veneer after spraying treatment to ensure that it meets the design requirements and quality standards, and then proceed with packaging and transportation. This step requires the establishment of a sound quality inspection standard and system, strict testing and control of each link, to ensure that product quality meets standards and customer requirements.

6、 Summary

From the above introduction, it can be seen that the production method and process flow of perforated roller coated aluminum veneer are very complex and require multiple processing steps to complete. Only through strict production methods and processes can the quality and stability of perforated roller coated aluminum veneer be ensured, meeting the needs and expectations of customers. I hope this article can provide you with some useful reference information to help you better understand the production method and process flow of perforated roller coated aluminum veneer.

Customer service QQ

Customer service QQ