Industry information

Company News

- Fluorocarbon aluminum veneer: the new darling of the construction industry, the perfect combination of environmental protection and aesthetics!

- Hyperbolic aluminum veneer: innovative elements for future architectural art

- Aluminum veneer, low-key luxury in modern architecture

- Fluorocarbon aluminum veneer: the fashion darling of the aluminum industry, revealing its unique charm!

- Exploring punched aluminum veneer: the gateway to the charm of industrial aesthetics

Industry dynamics

- Fluorocarbon aluminum veneer: an innovative choice for architectural aesthetics

- Unveiling the Charm and Applications of Punched Aluminum Veneers

- Innovative design of subway station aluminum ceiling enhances passenger experience

- How to ensure the quality of aluminum veneer?

- Aluminum alloy material fluorocarbon aluminum veneer

Frequently asked questions

- Is there any restriction on the size customization of aluminum veneer?

- How does aluminum veneer provide the weather resistance required for modern buildings?

- What impact does aluminum veneer have on the durability of buildings?

- What is the antioxidant performance of aluminum veneer?

- What are the advantages of aluminum veneer compared to other building materials in modern architecture?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

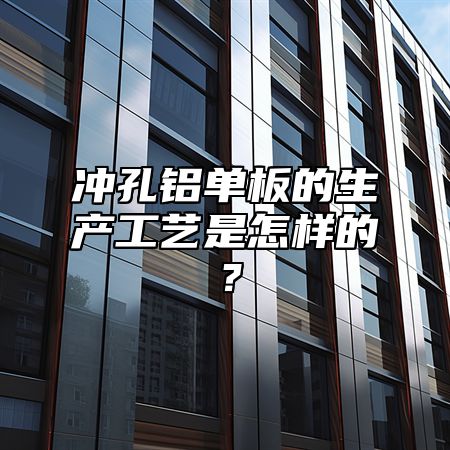

What is the production process of punched aluminum veneer?

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-07 18:11:59

- Click:0

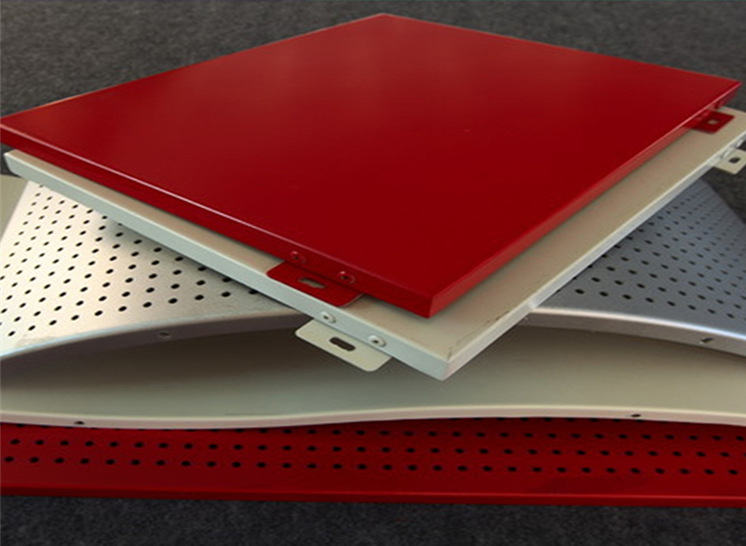

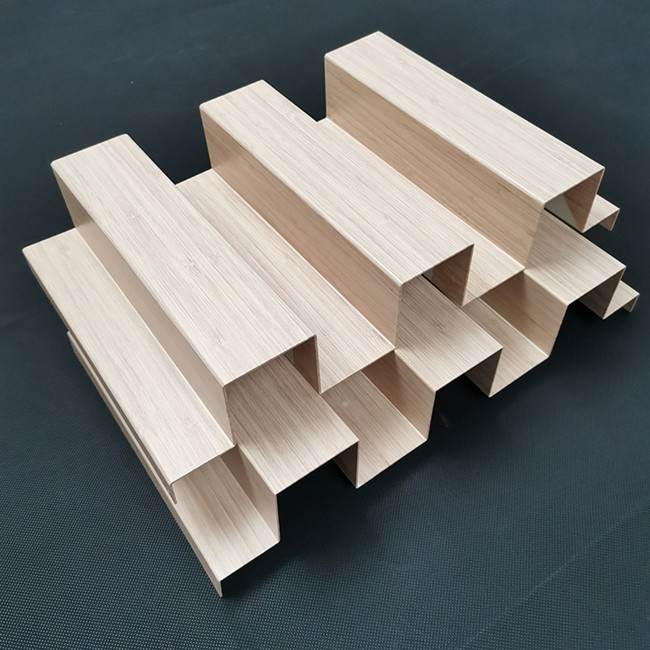

punchingAluminum veneerIt is a material widely used in the fields of architectural decoration, advertising billboards, curtain walls, etc. It has the advantages of light weight, high strength, corrosion resistance, fire prevention, etc. The production process of punched aluminum veneer generally includes the following steps:

1. Raw material preparation

The main raw materials for punched aluminum veneer are aluminum coils and punching molds of various specifications. Before production, it is necessary to inspect and screen the raw materials to ensure that the quality meets the requirements.

1. Cutting materials

Cut the aluminum coil according to the required width and length to obtain the desired size of aluminum sheet. Then the aluminum sheet is subjected to surface treatment, such as anodizing, to improve its corrosion resistance and aesthetics.

1. Punching

Place the processed aluminum sheet into a punching mold and perform punching processing using equipment such as punching machines or lasers. Punching processing can create holes of different shapes and sizes as needed to meet different design requirements.

1. Bending

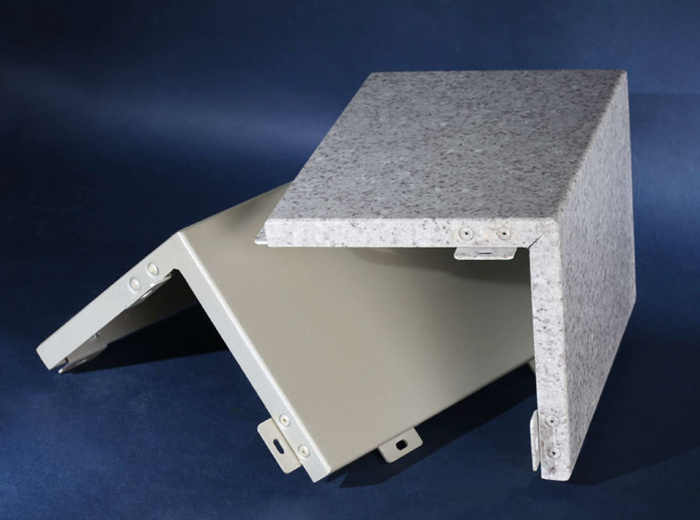

Bend the punched aluminum sheet into the desired shape and angle. Bending processing can be carried out by machine or manual, and the specific method depends on the requirements of the product.

1. Welding

Weld the bent aluminum sheet into a whole. Welding can be done using methods such as argon arc welding and TIG welding, depending on the requirements of the product.

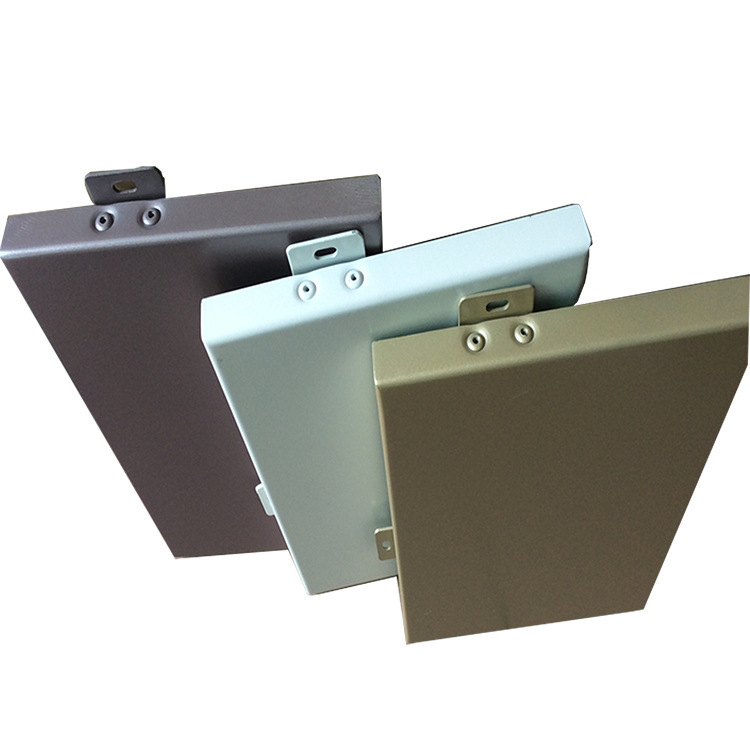

1. Surface treatment

Surface treatment of punched aluminum veneer after welding, such as spraying, anodizing, etc., to improve its corrosion resistance and aesthetics. At the same time, other surface treatments such as film coating, carving, etc. can be carried out as needed.

1. Packaging and shipping

The processed punched aluminum veneer is usually packaged in wooden boxes or pallets. Then transport it to the designated location for sale or installation.

The production process of punched aluminum veneer mainly includes steps such as raw material preparation, cutting, punching, bending, welding, surface treatment, and packaging for shipment. Each step requires strict quality control to ensure that the quality and performance of the final product meet the requirements.

- previous page:What is the price of punched aluminum veneer?

- Next page:Advantages of punched aluminum veneer

Customer service QQ

Customer service QQ