Industry information

Company News

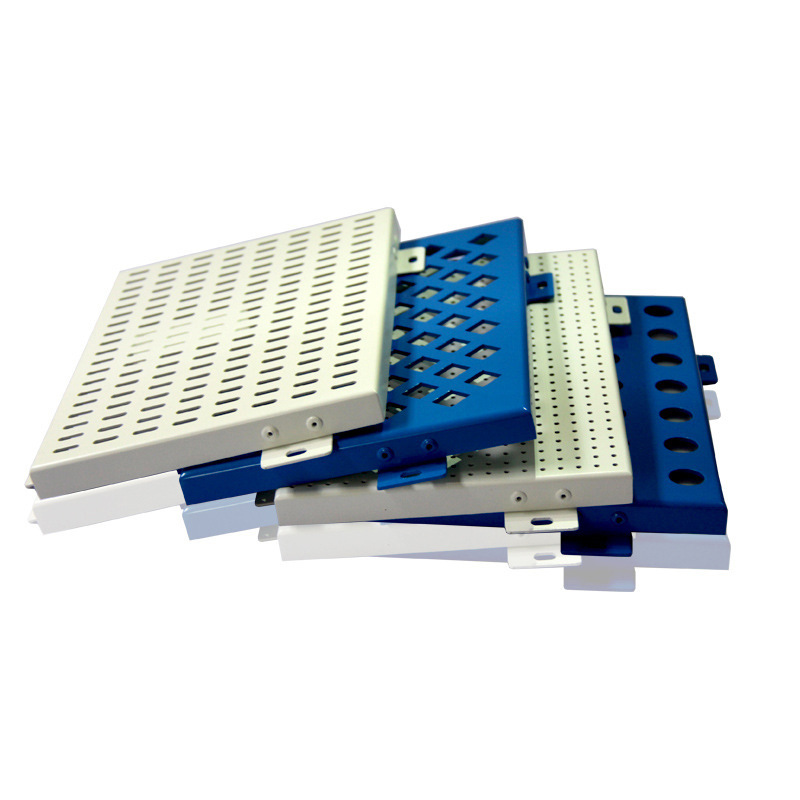

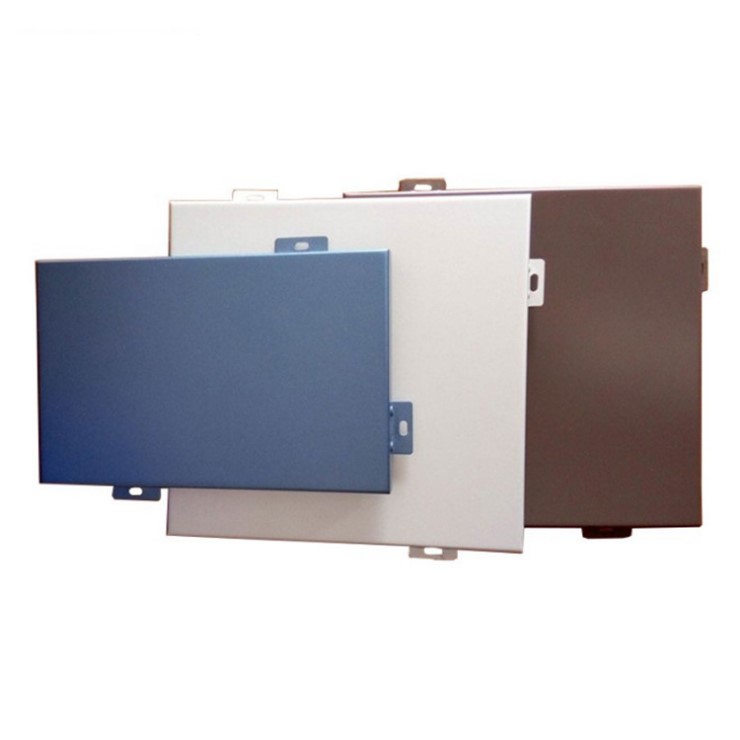

- Customize aluminum veneer to create personalized spatial aesthetics

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics

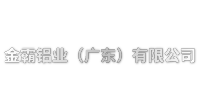

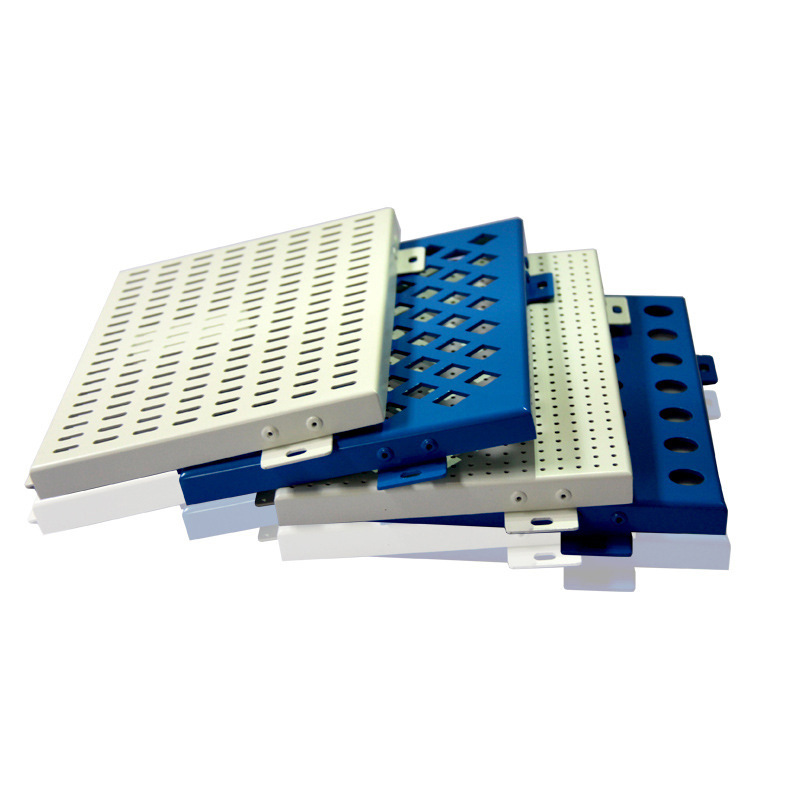

- Unlimited creativity, perforated aluminum veneer: the new favorite of fashionable architecture

- The Fashion Evolution of Aluminum Veneer: From Modern Simplicity to Personalized Customization

- Hyperbolic aluminum veneer: an artistic interpretation of modern architectural aesthetics

Industry dynamics

- Hyperbolic aluminum veneer: an elegant choice for creating modern architecture

- Hyperbolic Aluminum Veneer: Art and Technology in Modern Architecture

- Fluorocarbon aluminum veneer: a choice for light luxury, creating personalized spaces

- Using roller coating technology to refine the exterior aluminum veneer, making your building more textured

- Punched aluminum veneer: the new darling of modern architecture, revealing its charm!

Frequently asked questions

- What impact does aluminum veneer have on the durability of buildings?

- What is the seismic performance of aluminum veneer in building exterior design?

- Is there any restriction on the size customization of aluminum veneer?

- How does aluminum veneer provide the weather resistance required for modern buildings?

- What is the antioxidant performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Fluorocarbon aluminum veneer: the fashionable "coat" of modern architecture

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-19 20:18:32

- Click:0

Ladies and gentlemen, today let's talk about a little fresh thing in the construction industry - fluorocarbonAluminum veneerYou may think this name is a bit long, but don't underestimate it, it's a beautiful scenery in modern architecture!

We need to figure out what fluorocarbon aluminum veneer is. It is a building material made of aluminum plates that have undergone special processing. This material not only has a beautiful appearance but also excellent performance, making it a fashionable "coat" for modern architecture.

Imagine a high-rise building with only ordinary aluminum panels for its exterior walls, it would be too monotonous. But fluorocarbon aluminum veneer can help you find a bright color in the monotonous gray. It has a smooth surface, bright colors, and a rich texture, as if putting fashionable clothing on the building.

Fluorocarbon aluminum veneer also has good weather resistance. It can maintain good condition regardless of wind and rain, or exposure to sunlight and rain. This is equivalent to putting a sturdy "bulletproof vest" on the building, allowing you to live in peace of mind.

Speaking of which, you may be asking: If fluorocarbon aluminum veneer is so good, then it must be very expensive, right? In fact, although its price is slightly higher than ordinary aluminum plates, considering its excellent performance and aesthetics, the cost-effectiveness is still quite high.

I remember once I went to visit a newly built office building, and the exterior walls were made of fluorocarbon aluminum veneer. From a distance, that building looks like a huge white spaceship, parked on the city skyline. Entering the building, I found that its interior decoration is also very modern, giving people a fashionable and high-end feeling.

This reminds me of a building in my residential area, whose exterior walls are also made of fluorocarbon aluminum veneer. Every day when I come home from work and see that building, I am attracted by its beauty. Especially in the evening, the afterglow of the setting sun on the buildings is so beautiful that it is intoxicating.

The application scenarios of fluorocarbon aluminum veneer are not limited to office buildings and residential areas. It can also be used in public places such as schools, hospitals, and shopping malls. In these places, fluorocarbon aluminum veneer can showcase its unique charm.

How is fluorocarbon aluminum veneer made? It mainly goes through the following steps:

1. Raw material selection: Select high-quality aluminum plates as raw materials to ensure product quality.

2. Surface treatment: The aluminum plate is subjected to surface treatments such as sandblasting and anodizing to enhance its wear resistance and corrosion resistance.

3. Coating: Apply fluorocarbon paint on the treated aluminum plate to give the surface excellent weather resistance.

4. Assembly: Cut and assemble the coated aluminum plate into the desired shape and size.

5. Acceptance: Strictly inspect the finished product to ensure its quality meets the standards.

In this process, every step is crucial. Only carefully crafted fluorocarbon aluminum veneer can showcase its charm.

Fluorocarbon aluminum veneer, as a new type of material in modern architecture, not only has the advantages of beauty, durability, and environmental protection, but also adds a bright color to our city. Perhaps in the near future, we will see more buildings like this appearing around us, making our lives better.

Customer service QQ

Customer service QQ