Industry information

Company News

- Fluorocarbon aluminum veneer: the "supermodel" of the aluminum industry and the "darling" of the decoration industry

- The Charm of Aluminum Veneer: The Perfect Fusion of Lightweight and Texture

- Have you noticed that the appearance of these buildings has become particularly distinctive recently? For example

- Aluminum veneer customization, creating a new trend of personalized space!

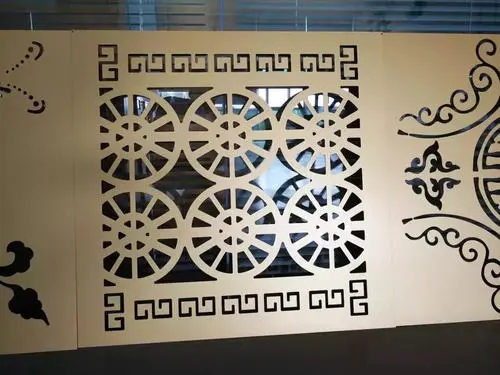

- Punched aluminum veneer: innovative building materials, the finishing touch of fashionable architecture

Industry dynamics

- Unveiling the perfect combination of fashion and practicality in hyperbolic aluminum veneer!

- Reliability and stability evaluation of 1.5mm aluminum veneer

- Aluminum veneer: the fashionable choice in modern architecture?

- Innovative design and construction process analysis of curved ceiling aluminum veneer

- Aluminum veneer: understated luxury in modern architecture

Frequently asked questions

- Can aluminum veneer be used for building insulation design?

- What is the seismic performance of aluminum veneer in building exterior design?

- Is the production process of aluminum veneer environmentally friendly?

- Can the insulation function of aluminum veneer reduce the energy consumption of buildings?

- Is there any restriction on the size customization of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

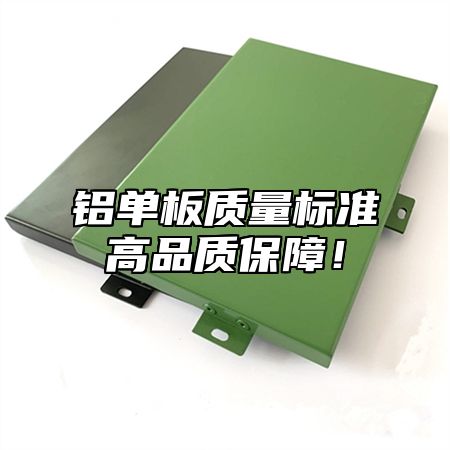

Aluminum veneer quality standard, high-quality guarantee!

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 19, 2025 23:26:43

- Click:0

Aluminum veneerAs a new type of building material, its quality standards and quality assurance have always been a focus of consumer attention. In the market, there are some low-quality and counterfeit aluminum veneer products that have caused great inconvenience to consumers. It is very important to understand the quality standards and quality assurance measures of aluminum veneer, which can help consumers choose high-quality aluminum veneer products.

1、 Raw material quality control

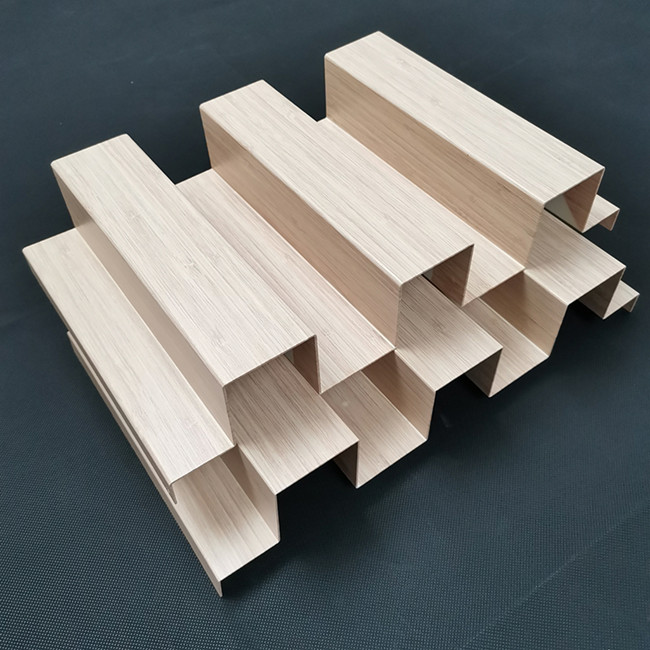

The quality of aluminum veneer first depends on the quality of the raw materials. High quality aluminum veneer should be made of high-quality aluminum alloy materials with high strength and corrosion resistance. Aluminum veneer manufacturers need to conduct strict quality testing and screening of raw materials to ensure that the selected materials meet relevant national standards and technical requirements.

2、 Production process control

The production process of aluminum veneer is also one of the important factors affecting its quality. High quality aluminum veneer should adopt advanced production processes and equipment to ensure that there are no problems or defects during the production process. Aluminum veneer manufacturers also need to establish a comprehensive quality management system to monitor and manage the entire production process, ensuring that product quality meets national standards and technical requirements.

3、 Surface treatment control

The surface treatment of aluminum veneer is also one of the important factors affecting its quality. High quality aluminum veneer should undergo fine surface treatment processes such as spraying, anodizing, etc. to improve its corrosion resistance and aesthetics. Aluminum veneer manufacturers also need to conduct strict quality inspection and control of the surface treatment process to ensure that the product surface quality meets national standards and technical requirements.

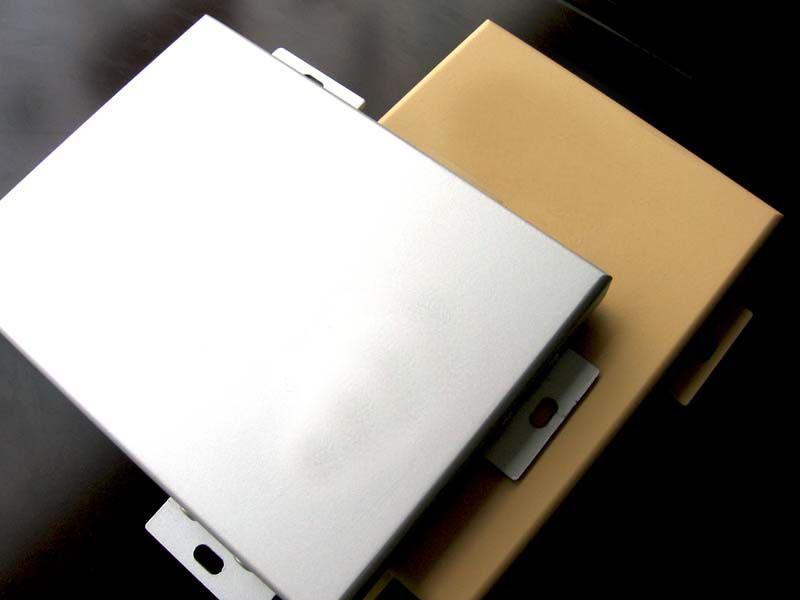

4、 Quality inspection and control

The quality inspection of aluminum veneer is one of the important means to ensure its quality. High quality aluminum veneer should undergo multiple rigorous quality inspections and tests, such as strength testing, corrosion resistance testing, appearance inspection, etc., to ensure that the product's performance meets national standards and technical requirements. Aluminum veneer manufacturers also need to establish a sound quality inspection system, conduct comprehensive testing and inspection of each batch of products, and ensure stable and reliable product quality.

5、 After sales service guarantee

High quality aluminum veneer not only requires high-quality products themselves, but also needs to provide comprehensive after-sales service guarantee. Aluminum veneer manufacturers should establish a comprehensive after-sales service system to provide customers with timely and professional technical support and service guarantees, solve problems and difficulties encountered by customers during use, and improve customer satisfaction and loyalty.

6、 Summary

The quality standards and quality assurance measures for aluminum veneer mainly include raw material quality control, production process control, surface treatment control, quality inspection control, and after-sales service guarantee. Consumers should choose brands and manufacturers with good reputation and credibility when purchasing aluminum veneer, and carefully check the relevant information and quality certification certificates of the products to ensure the purchase of high-quality aluminum veneer products.

Customer service QQ

Customer service QQ