Industry information

Company News

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum veneer, the "invisible" protector of modern architecture

- Explore the charm of fluorocarbon aluminum veneer and create a modern and fashionable space!

- Aluminum plate punching, the behind the scenes hero of space new fashion

- Aluminum veneer: making buildings safer and more reliable

Industry dynamics

- Aluminum veneer customization, creating personalized spatial aesthetics

- Design and expressive power of 3mm aluminum veneer

- Aluminum veneer: understated luxury in modern architecture

- Precautions for Aluminum Ceiling Decoration in Living Room

- Aluminum veneer new chapter: not just sheet metal, but also a display of art

Frequently asked questions

- Is there any restriction on the size customization of aluminum veneer?

- What are the advantages of aluminum veneer compared to other building materials in modern architecture?

- What is the sound absorption effect of aluminum veneer?

- What is the antioxidant performance of aluminum veneer?

- Can the insulation function of aluminum veneer reduce the energy consumption of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How can aluminum veneer meet the waterproof performance requirements of modern buildings?

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-14 08:14:59

- Click:0

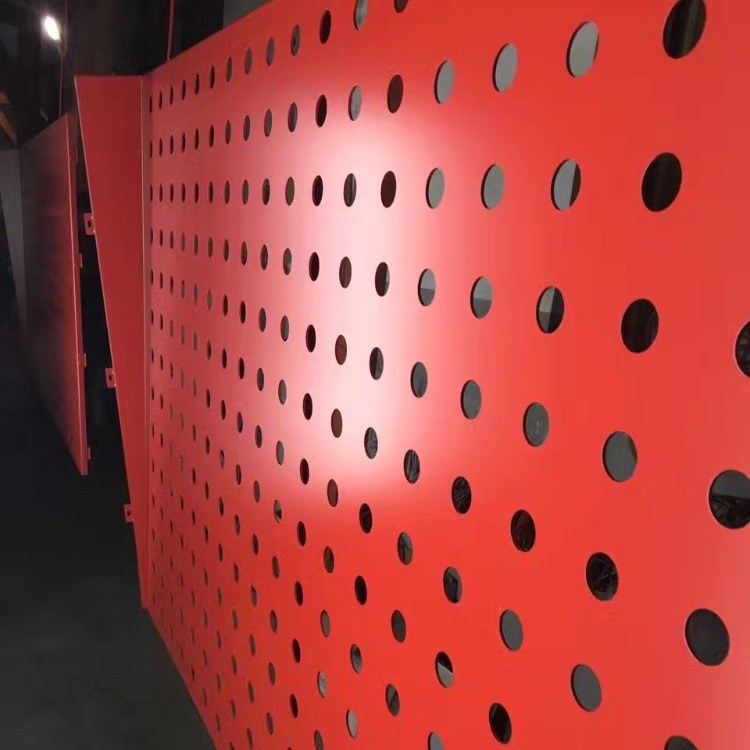

The demand for waterproof performance in modern architecture is increasing, andAluminum veneerAs a new type of building material, it also needs to have good waterproof performance to meet this requirement. This article will provide a detailed introduction from multiple perspectives on how aluminum veneer meets the waterproof performance requirements of modern buildings.

1、 Surface treatment

The surface treatment of aluminum veneer is one of the important means to ensure its waterproof performance. Generally speaking, the surface of aluminum veneer is treated with fluorocarbon spraying, anodizing and other processes to improve its corrosion resistance and wear resistance. These processing techniques can not only increase the surface hardness and glossiness of aluminum veneer, but also form a dense oxide film, effectively preventing moisture from penetrating into the interior of the aluminum veneer.

2、 Sealing strip

During the installation process of aluminum veneer, it is necessary to use sealing strips to fill the gap between the aluminum veneer and the keel to prevent moisture from penetrating into the interior of the aluminum veneer. Generally speaking, sealing strips should be made of materials with good water resistance and weather resistance, and undergo strict quality control and testing to ensure their waterproof performance and service life.

3、 Structural Design

The structural design of aluminum veneer is also an important factor in ensuring its waterproof performance. Generally speaking, the structure of aluminum veneer should have high strength and stiffness to ensure that it is not easily deformed or cracked under the influence of factors such as water pressure and temperature changes. It is also necessary to install sound insulation or thermal insulation layers between the aluminum veneers to reduce the evaporation and condensation of moisture caused by air circulation.

4、 Material selection

The material selection of aluminum veneer is also an important factor in ensuring its waterproof performance. Generally speaking, high-quality aluminum with high water resistance and corrosion resistance should be selected as the raw material for aluminum veneer, and appropriate surface treatment processes should be adopted to improve its water resistance and corrosion resistance. Aluminum veneers of different thicknesses and shapes can also be selected according to specific needs to meet different building requirements.

Aluminum veneer can meet the waterproof performance requirements of modern buildings through multiple means such as surface treatment, sealing strips, structural design, and material selection. Only by fully considering these factors and taking corresponding measures for optimization and control, can the advantages of aluminum veneer be fully utilized to provide safer, more aesthetically pleasing, and environmentally friendly solutions for buildings.

- previous page:Aluminum veneer cleaning and maintenance guide

- Next page:Aluminum veneer color matching guide

Customer service QQ

Customer service QQ