Industry information

Company News

- Aluminum veneer, low-key luxury in modern architecture

- Aluminum veneer: the elegant coat of modern architecture

- Unveiling Hyperbolic Aluminum Veneer: A Fashionable Choice in Modern Architecture

- Aluminum veneer: not just a building material, it is the soul of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Exploring Hyperbolic Aluminum Veneer: The Behind the Scenes Hero of Aluminum's New Fashion

- Comparative analysis of aluminum veneer curtain wall prices

- Hyperbolic Aluminum Veneer: Aesthetic Innovation for Future Architecture

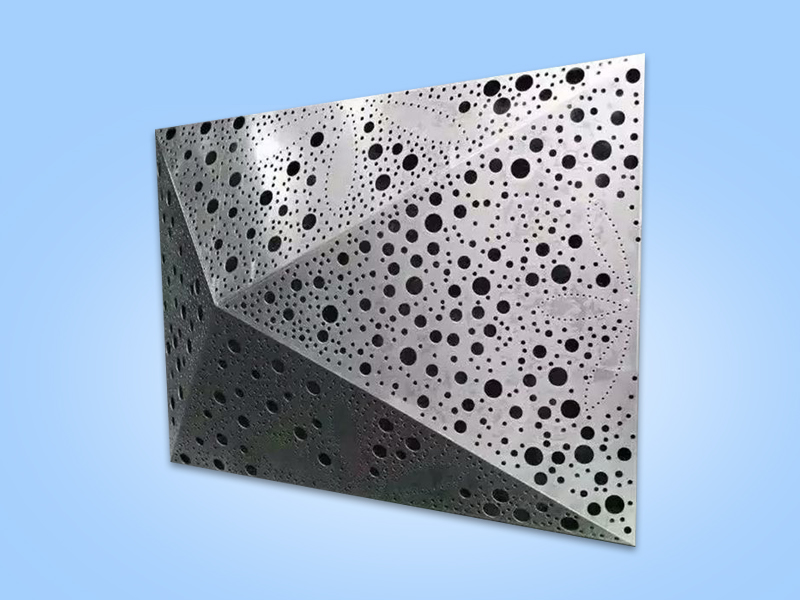

- Application of hollow punched aluminum veneer in modern architecture

- What are the advantages of aluminum veneer in terms of environmental protection?

Frequently asked questions

- What is the seismic performance of aluminum veneer in building exterior design?

- What impact does aluminum veneer have on the durability of buildings?

- What is the antioxidant performance of aluminum veneer?

- What is the sound absorption effect of aluminum veneer?

- Can the insulation function of aluminum veneer reduce the energy consumption of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the cold bending resistance of fluorocarbon aluminum veneer?

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-15 23:02:59

- Click:0

FluorocarbonAluminum veneerIt is a building material widely used in fields such as architecture, billboards, curtain walls, etc. In addition to its excellent weather resistance, corrosion resistance, and decorative properties, fluorocarbon aluminum veneer also has certain cold bending resistance. The following will provide a detailed introduction to the cold bending resistance and influencing factors of fluorocarbon aluminum veneer.

1. Definition of Cold Bending Resistance

Cold bending resistance refers to the ability of a material to maintain its original shape and size after being subjected to low temperatures. In architecture, cold bending resistance is commonly used to evaluate the load-bearing capacity and stability of materials.

1. Cold bending resistance of fluorocarbon aluminum veneer

The cold bending resistance of fluorocarbon aluminum veneer is related to factors such as its material and production process. High quality fluorocarbon aluminum veneer is usually made of high-strength aluminum alloy material, which is precision processed and treated to form a hard oxide film on its surface, thereby improving its hardness and wear resistance. Fluorocarbon aluminum veneer also has good plasticity and toughness, which can effectively control its cold bending resistance.

It should be noted that the cold bending resistance of fluorocarbon aluminum veneer is not absolute, and its performance is influenced by various factors such as material quality, usage environment, thickness, etc. When using fluorocarbon aluminum veneer, it is necessary to choose and design according to the specific situation, and follow the manufacturer's instructions and maintenance suggestions to ensure the service life and stable performance of fluorocarbon aluminum veneer.

Fluorocarbon aluminum veneer has certain cold bending resistance, which can improve its load-bearing capacity and stability to a certain extent. However, the specific resistance to cold bending still needs to be evaluated and determined based on factors such as material characteristics and production processes. Consumers should choose fluorocarbon aluminum veneer products that meet the standards and follow the manufacturer's instructions and maintenance recommendations to ensure the service life and stable performance of fluorocarbon aluminum veneer. Attention should also be paid to the characteristics of materials and structural limitations during design and installation to ensure that the construction effect meets the requirements.

Customer service QQ

Customer service QQ