Industry information

Company News

- Hyperbolic aluminum veneer: an innovative choice in architectural aesthetics

- Hyperbolic aluminum veneer: the fashionable choice for modern architecture?

- Aluminum veneer: making buildings safer and more reliable

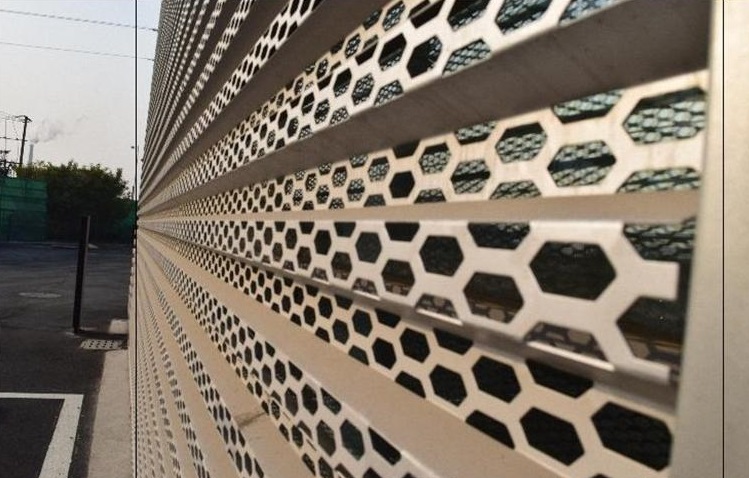

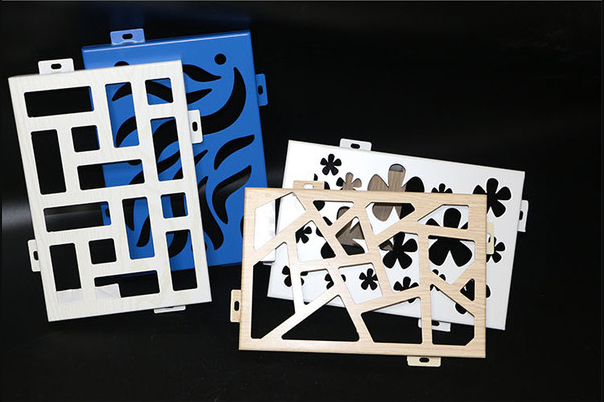

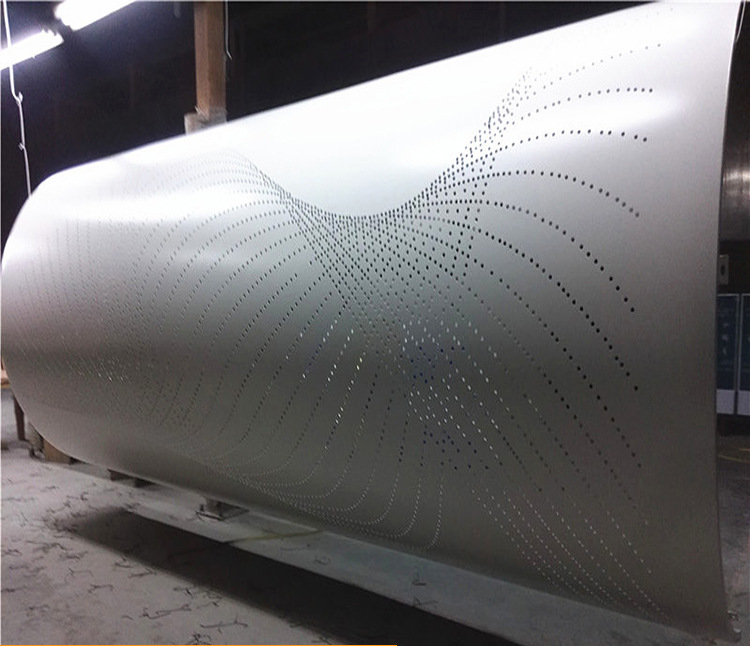

- Aluminum veneer punching, infinite creative space art

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics

Industry dynamics

- Aluminum veneer: the 'invisible star' of the construction industry

- Aluminum veneer: the fashionable coat of architecture, revealing the secrets behind it

- Aluminum veneer customization with reasonable price, transparent and invisible consumption

- Aluminum veneer customization, creating the art of personalized space

- Hyperbolic 2.0mm aluminum veneer creates a permanent and durable exterior wall decoration material

Frequently asked questions

- Can aluminum veneer be used for building insulation design?

- Is there any restriction on the size customization of aluminum veneer?

- What impact does aluminum veneer have on the durability of buildings?

- What are the advantages of aluminum veneer compared to other building materials in modern architecture?

- What is the seismic performance of aluminum veneer in building exterior design?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Introduction to the production process of 3mm aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-05 00:49:08

- Click:0

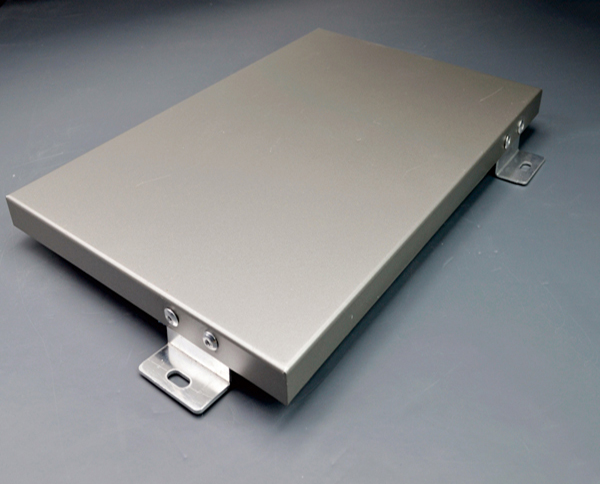

3mmAluminum veneerAs a new type of building material, its manufacturing process is the key to ensuring product quality and performance. The following will provide a detailed introduction to the manufacturing process of 3mm aluminum veneer from multiple aspects.

1、 Material preparation

The production of 3mm aluminum veneer first requires the preparation of the required materials, including aluminum alloy sheets, surface treatment agents, spraying equipment, roller coating equipment, etc. Aluminum alloy sheet is the core material for producing 3mm aluminum veneer, which requires the selection of high-quality and uniform thickness raw materials, and strict inspection and screening.

2、 Surface treatment

Before making 3mm aluminum veneer, it is necessary to perform surface treatment on the aluminum alloy sheet to improve its corrosion resistance and decorative performance. Common surface treatment methods include anodizing, spraying, roller coating, etc. Anodizing is a commonly used surface treatment method that can form a hard, wear-resistant, and corrosion-resistant oxide film, improving the performance and aesthetics of aluminum alloy sheets.

3、 Cutting and processing

After surface treatment, it is necessary to cut and process the aluminum alloy sheet to obtain the desired size and shape. Cutting and processing are usually carried out using advanced equipment such as CNC machine tools or laser cutting machines, which can achieve high-precision and high-efficiency processing.

4、 Coating treatment

After the cutting process is completed, the aluminum alloy sheet needs to be coated to increase its decorative and corrosion resistance. Common coating treatment methods include spraying, roller coating, etc. Spray coating is a commonly used coating treatment method, which can evenly spray the coating on the surface of aluminum alloy sheet through spraying equipment, forming a beautiful and corrosion-resistant coating.

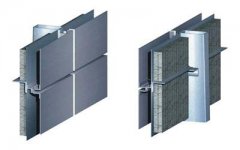

5、 Installation and construction

After completing the coating treatment, it is necessary to install 3mm aluminum veneer onto the building. Installation and construction are usually carried out by lifting, fixing, and other methods. Attention should be paid to factors such as installation position, angle, and strength to ensure the safety and stability of aluminum veneer.

6、 Case Presentation

The following is a successful case study of the production process of 3mm aluminum veneer: A commercial building used 3mm aluminum veneer as the exterior wall decoration material. Through reasonable material preparation, surface treatment, cutting processing, coating treatment, and installation construction, modern and concise visual effects were achieved. The commercial building is located in a bustling area in the city center, with frequent commercial activities in the surrounding area, therefore it has high commercial value and development prospects. After years of practical application and improvement, this commercial building has become one of the landmark buildings in the local area.

The production process of 3mm aluminum veneer is the key to ensuring product quality and performance. By making reasonable efforts in material preparation, surface treatment, cutting and processing, coating treatment, and installation construction, the best decorative effect and social benefits can be achieved. In future architectural design, more attention should be paid to the research and development of the production process of 3mm aluminum veneer, in order to achieve longer, more beautiful, and more practical building effects.

Customer service QQ

Customer service QQ