Industry information

Company News

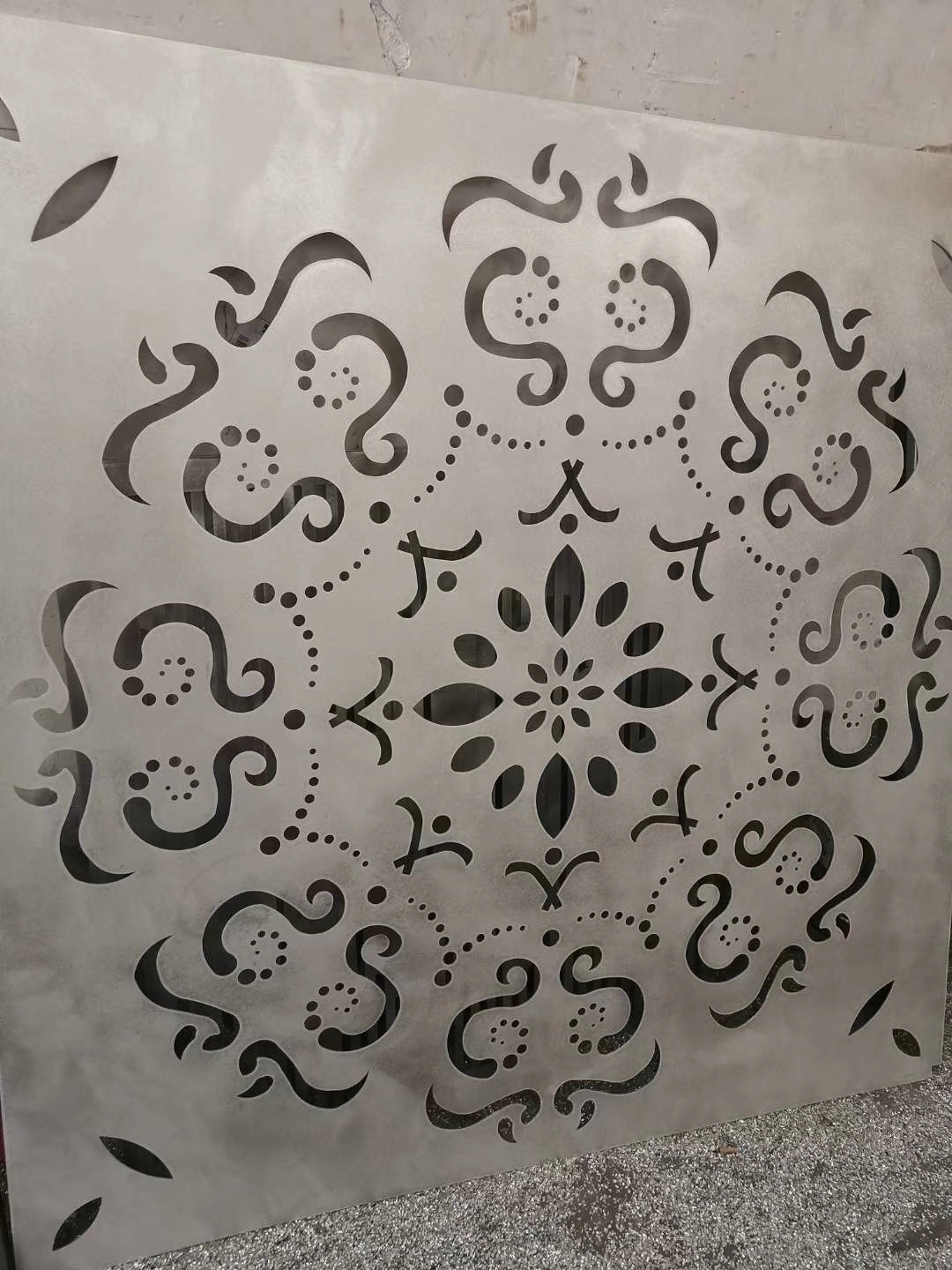

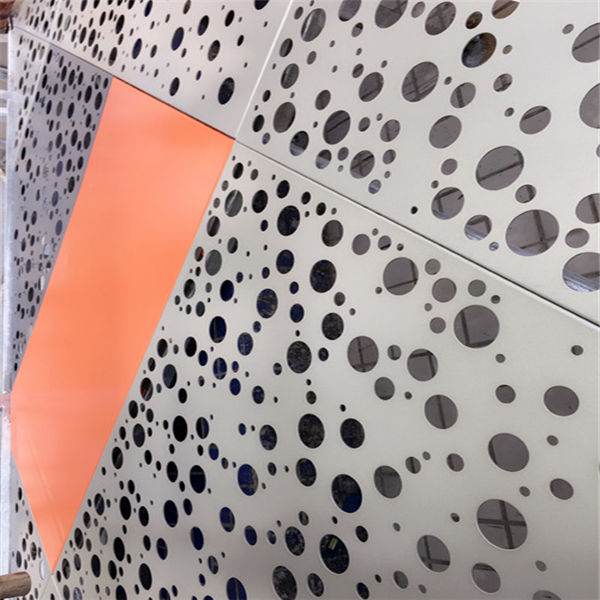

- New Talent in Aluminum Plate: Fashion and Practical Journey of Punched Aluminum Veneer

- 2. "Explore the unique charm of hyperbolic aluminum veneer" 3 Hyperbolic aluminum veneer: Creating a

- 2. "Exploring Hyperbolic Aluminum Veneer: An Architectural Miracle of Art and Technology Dancing Together!" 3 "...

- Unveiling Hyperbolic Aluminum Veneer: The New Favorite of Fashion Architecture!

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

Industry dynamics

- Aluminum veneer customization, creating a new proposition for personalized space!

- Exploring Hyperbolic Aluminum Veneer: The New Favorite of Future Architecture?

- Aluminum veneer customization, creating personalized space and new fashion

- Analysis of Production Cost and Market Price Investment Potential of Aluminum Veneer

- Hyperbolic aluminum veneer, a masterpiece of art in the aluminum industry!

Frequently asked questions

- Can the insulation function of aluminum veneer reduce the energy consumption of buildings?

- What is the antioxidant performance of aluminum veneer?

- What is the seismic performance of aluminum veneer in building exterior design?

- Is there any restriction on the size customization of aluminum veneer?

- Can aluminum veneer be used for building insulation design?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

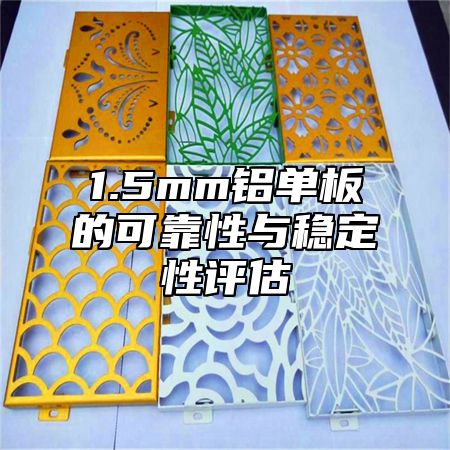

Reliability and stability evaluation of 1.5mm aluminum veneer

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 25, 2025 18:47:18

- Click:0

1.5mmAluminum veneerIt is a very common building material, and its reliability and stability are of great significance for ensuring the safety and durability of buildings. This article will provide a detailed introduction to the reliability and stability evaluation of 1.5mm aluminum veneer.

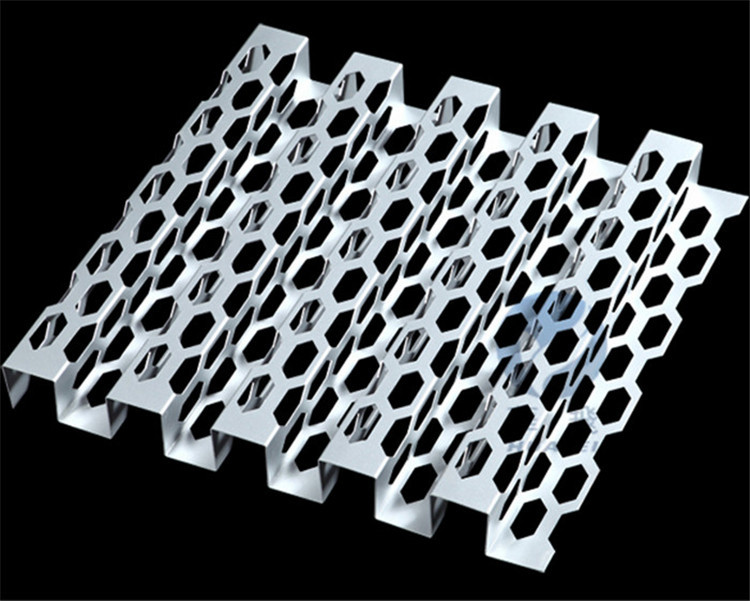

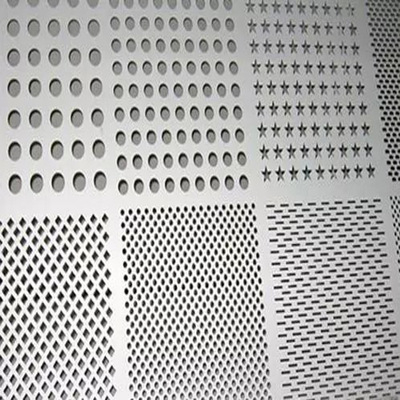

In terms of material properties, 1.5mm thick aluminum veneer typically has a certain level of reliability and stability. This is because the main component of aluminum veneer is aluminum alloy, which has good strength and stiffness, and can withstand large loads and external forces, thereby ensuring the stability and safety of aluminum veneer. The surface of aluminum veneer can also be treated with some special processes, such as anodizing, spraying, etc., to further improve its reliability and stability.

In terms of installation and construction, attention should also be paid to some details. For example, when installing aluminum veneer, it is necessary to ensure its sealing with the building wall to reduce the impact of air, water, steam, etc. on the building; During use, it is necessary to avoid excessive contact with fire sources and high-temperature environments to prevent deformation or damage to the aluminum veneer; Regular inspections and maintenance are also required to maintain the reliability and stability of the aluminum veneer.

Again, during the design and construction process, specialized measures can also be taken to improve the reliability and stability of aluminum veneer. For example, setting up reinforcement layers inside the wall, using reinforcement materials, adding waterproof layers, etc. These measures can effectively enhance the load-bearing capacity and protective ability of aluminum veneer, and improve the reliability and stability of aluminum veneer.

In terms of quality inspection and acceptance, it is also necessary to check and evaluate the reliability and stability of aluminum veneer. During this process, attention should be paid to factors such as the dimensional accuracy, surface smoothness, and color uniformity of the aluminum veneer to ensure its reliability and stability meet the requirements.

The reliability and stability of 1.5mm thick aluminum veneer are one of its very important advantages. In practical applications, attention should be paid to the quality and effectiveness of the selected materials to ensure better decorative and usage effects, while also paying attention to the reliability and stability of the materials and construction details.

Customer service QQ

Customer service QQ