Industry information

Company News

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Fluorocarbon aluminum veneer: a new favorite in architecture, combining beauty and durability

- Aluminum veneer customization, creating a new trend of personalized space

- Hyperbolic aluminum veneer: a new luxury in aluminum materials and a unique choice for architectural aesthetics

- Punched aluminum veneer: the fashionable choice for modern architecture?

Industry dynamics

- Aluminum veneer production enterprises offer reasonable prices and operate with integrity

- Punched aluminum veneer: infinite creativity, the "invisible" soul of fashionable architecture

- How to choose aluminum curtain wall panels suitable for indoor environments

- Analysis of Quality Assurance and Technical Advantages of Wave 1.5mm Aluminum Veneer

- Aluminum veneer is not just the charm of building materials

Frequently asked questions

- What are the advantages of aluminum veneer compared to other building materials in modern architecture?

- What is the sound absorption effect of aluminum veneer?

- Is there any restriction on the size customization of aluminum veneer?

- What is the seismic performance of aluminum veneer in building exterior design?

- What is the antioxidant performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786@qq.com

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the surface treatment methods for hyperbolic aluminum veneer?

- Author: Jinba Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 15, 2025 17:15:10

- Click:0

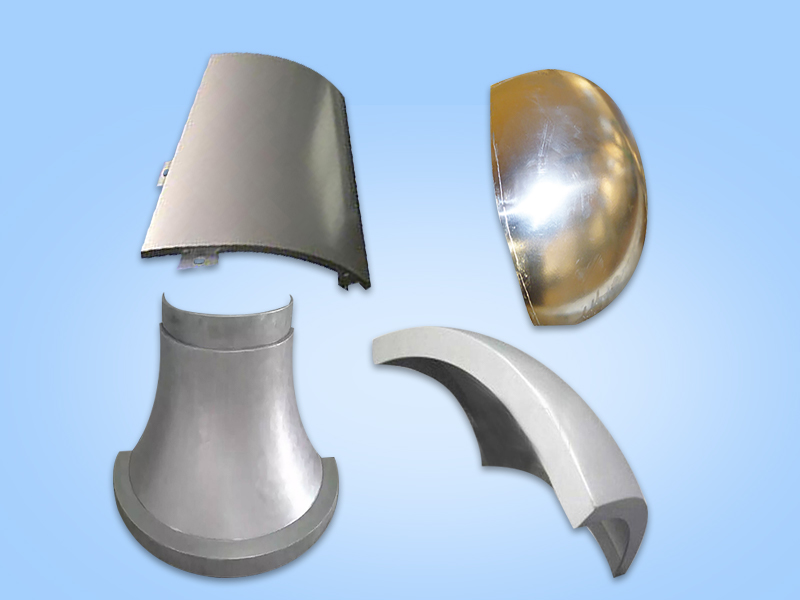

hyperbolicAluminum veneerAs a new type of building material, it has the advantages of lightweight, high strength, and corrosion resistance, and is widely used in various fields such as building decoration, curtain wall engineering, and roof engineering. In the production process of hyperbolic aluminum veneer, surface treatment is also a very important step. Below is a detailed introduction to the surface treatment methods of hyperbolic aluminum veneer.

Anodizing treatment is a common surface treatment method for hyperbolic aluminum veneer. By using hyperbolic aluminum veneer as an anode and conducting electrochemical reactions in the electrolyte, a dense oxide film is formed on its surface, thereby improving its corrosion resistance and wear resistance. After anodizing treatment, the hyperbolic aluminum veneer also has a certain decorative effect, which can present different colors and textures.

Spray coating is also a common surface treatment method for hyperbolic aluminum veneer. By placing the hyperbolic aluminum veneer into the spray booth and using a spray gun to spray various colors and patterns of paint on its surface, a unique decorative effect is formed. Spraying treatment can also improve the weather resistance and wear resistance of hyperbolic aluminum veneer.

Again, wire drawing treatment is also a common surface treatment method for hyperbolic aluminum veneer. By using a special wire drawing machine to pull out fine thread like patterns on the surface of hyperbolic aluminum veneer, the decorative effect and texture are improved. Wire drawing treatment can also increase the strength and hardness of hyperbolic aluminum veneer.

Finally, it should be noted that when choosing hyperbolic aluminum veneer, the selection should be based on actual needs and budget factors, and hyperbolic aluminum veneer products with good quality and service should be chosen. During the application process, corresponding waterproof measures, anti-corrosion measures, and fire prevention measures should be taken to ensure the safety and health of the building.

There are various surface treatment methods for hyperbolic aluminum veneer, including anodizing treatment, spraying treatment, wire drawing treatment, etc. We should closely monitor the latest developments and application cases in the hyperbolic aluminum veneer market, and actively promote the application and development of hyperbolic aluminum veneer in various fields. During the application process, attention should be paid to construction quality and safety issues to avoid potential safety hazards and quality problems.

Customer service QQ

Customer service QQ